Introduction

Interlining is a hidden layer in clothing that adds strength, structure, and durability. It is placed between fabric layers to support the shape of a garment. Without interlining, many clothes would lose their form, wrinkle easily, or wear out faster.

Interlining improves the fit of jackets, shirts, and dresses. It makes collars, cuffs, and waistbands firm and long-lasting. In high-quality suits and coats, Interlining ensures a polished look.

There are two main types: fusible (attached with heat) and sew-in (stitched inside). The material used depends on fabric type and garment design.

Choosing the right Interlining is key to making clothes last longer and look better. It is widely used in tailoring, fashion, and industrial clothing. Understanding Interlining helps manufacturers create high-quality, comfortable, and durable garments.

What Is Interlining in Clothing?

Interlining is a layer of fabric placed between the main fabric and the lining of a garment. It gives clothing structure, support, and durability. This hidden layer helps maintain the shape of garments, preventing wrinkles and sagging.

Interlining is commonly used in collars, cuffs, waistbands, and tailored clothing. It strengthens these areas, making them last longer. Without interlining, many clothes would lose their form after a few washes.

There are two main types of interlining: fusible and sew-in. Fusible Interlining sticks to the fabric when heat and pressure are applied. It is easy to use and commonly found in modern garments. Sew-in interlining is stitched into clothing, offering flexibility and comfort.

Manufacturers choose interlining based on fabric type and garment design. It plays a key role in producing high-quality, well-structured clothing. Proper interlining use improves durability, fit, and overall appearance.

Why Is Interlining Used in Garments?

Interlining strengthens and shapes garments. It adds support to fabrics, making them more durable and long-lasting. Without interlining, clothes can lose shape, wrinkle easily, or wear out faster.

It is mainly used in collars, cuffs, waistbands, and structured garments like suits and coats. These areas need extra stiffness and stability. Interlining helps garments keep their original form after multiple washes and daily wear.

Interlining also improves comfort. It prevents fabric from stretching too much and provides a smooth finish. It enhances the fit of tailored clothing, giving a polished look.

Different types of Interlining are chosen based on fabric and garment type. Lightweight interlining works for soft fabrics, while heavier Interlining supports structured designs.

What Are the Different Types of Interlining?

Interlining is an extra layer between the outer fabric and lining. It adds strength, shape, and durability to clothing. Different types of Interlining are available based on how they are applied and the materials used.

Types Based on Application

Fusible Interlining

Fusible Interlining has an adhesive coating. It sticks to the fabric when heat and pressure are applied. It is easy to use and speeds up production. It provides strong support and is widely used in modern clothing.

Sew-in Interlining

Sew-in interlining is stitched between fabric layers. It does not use adhesives, making it more breathable. It is ideal for high-quality and delicate garments. It offers flexibility and a softer feel.

Types Based on Material

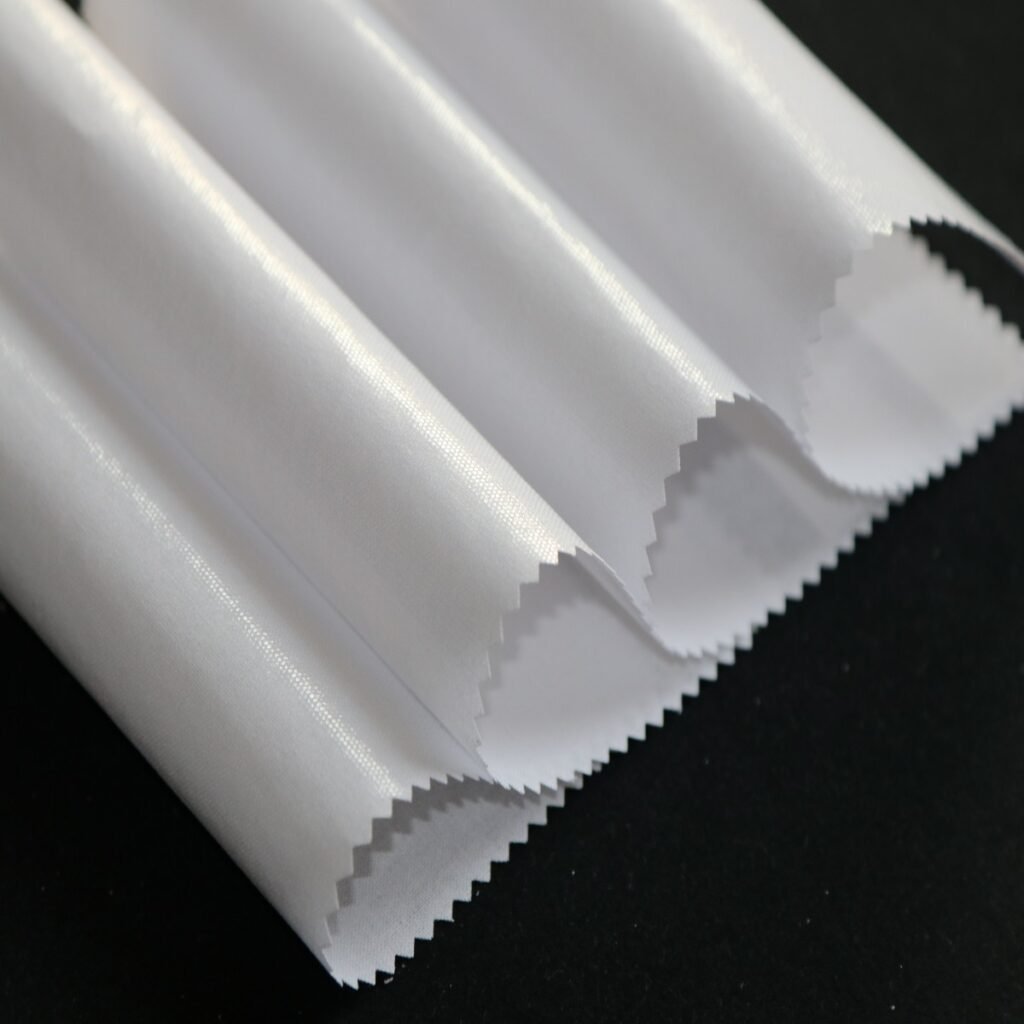

Woven Interlining

Woven interlining is made from woven fabric. It is strong, durable, and stable. It is used in structured garments like suits, coats, and formal wear.

Non-Woven Interlining

Non-woven interlining is made from bonded fibres instead of woven threads. It is lightweight and cost-effective, and it is commonly used in casual wear and budget clothing.

Knitted Interlining

Knitted Interlining is made from knitted fabric. It stretches with the garment, perfect for stretchable fabrics like jerseys and sportswear. It provides flexibility and comfort.

Choosing the Right Interlining

The right Interlining depends on the fabric and garment design. Light fabrics need soft Interlining to maintain drape, heavy fabrics need strong interlining for structure, and stretchable fabrics need flexible Interlining for comfort.

Manufacturers use different interlinings to improve garment quality. Fusible Interlining is common in mass production. Sew-in interlining is preferred for high-end clothing. Woven interlining is best for formal wear. Non-woven interlining is budget-friendly. Knitted interlining works for stretch fabrics.

Where Is Interlining Used in Clothing?

Interlining is used in different clothing parts to provide support, shape, and durability. It strengthens fabrics and helps garments maintain their form over time.

Formal and Tailored Wear

- Suits and Blazers: Interlining adds stiffness to lapels, chest areas, and pockets.

- Dress Shirts: These are used in collars and cuffs to maintain a crisp look.

- Trousers and Skirts: Supports waistbands for a firm fit.

Everyday Clothing

- Polo Shirts: Keeps collars from curling.

- Casual Jackets and Coats: Adds warmth and shape.

- Denim Wear: Reinforces waistbands and pockets.

Special Garments

- Bridal and Evening Wear: Gives structure to bodices and flared skirts.

- Sportswear and Uniforms: Enhances durability and flexibility.

What Are the Benefits of Using Interlining?

Some of the benefits of using Interlining are given below.

- Enhances structure by helping garments hold their form.

- Increases durability by reinforcing fabric and extending lifespan.

- Improves fit by providing better shaping for a polished look.

- Adds comfort by preventing the fabric from stretching too much.

- Reduces wrinkles by helping fabrics resist creasing.

- Supports flexibility while allowing movement in specific designs.

- Enhances garment performance by maintaining quality after multiple washes.

How to Choose the Right Interlining for Different Fabrics?

Choosing the right Interlining depends on the fabric and clothing design. The wrong Interlining can make clothes uncomfortable or lose shape.

For soft fabrics like silk and chiffon, use lightweight Interlining. It keeps the fabric flexible. Medium-weight interlining works best for cotton, polyester, and linen. It adds support without making the fabric too stiff. Heavy fabrics like wool, denim, and leather need strong Interlining. It helps them hold their shape.

Fusible Interlining is easy to apply and sticks to fabric using heat. Sew-in interlining is stitched inside and is better for high-quality clothing. Woven interlining gives firm support. Non-woven interlining is lightweight and budget-friendly. Knitted Interlining is best for stretchy fabrics like jerseys.

What Are the Common Mistakes in Using Interlining?

Using the wrong Interlining can affect the quality of clothing. It can make garments uncomfortable, stiff, or lose shape quickly.

- Choosing the wrong type makes fabrics too stiff or too weak.

- Using heavy Interlining on light fabrics can ruin flexibility.

- Applying light interlining on heavy fabrics does not give enough support.

- Using too much heat on fusible Interlining can damage the fabric.

- Applying too little heat may cause weak bonding and peeling.

- Not pre-shrinking Interlining can lead to fabric distortion after washing.

- Placing interlining unevenly creates lumps and wrinkles.

- Skipping interlining in budget clothing reduces durability and shape retention.

How Can Interlining Be More Sustainable and Eco-Friendly?

Sustainable Interlining helps reduce waste and pollution. Choosing eco-friendly materials makes clothing safer for the environment.

Organic cotton interlining is a better choice. It does not use harmful chemicals. Bamboo-based Interlining is also good. It breaks down naturally and grows fast without chemicals. Recycled polyester interlining helps by reusing plastic waste.

Water-soluble Interlining disappears after use, reducing fabric waste. Avoiding toxic glue in fusible Interlining keeps harmful chemicals away. Plant-based dyes are safer than chemical dyes.

Using lightweight Interlining saves materials and reduces waste. Better factory methods can use less energy and water. Choosing brands that use eco-friendly Interlining helps the planet.

What Are the Future Trends in Interlining Technology?

Interlining technology is improving to make clothing better, stronger, and more eco-friendly. New methods help create durable and comfortable garments while reducing waste.Smart Interlining is one major trend. It can adjust to temperature changes, keeping clothes cool in summer and warm in winter, improving comfort and energy savings.

Another innovation is 3D-printed interlining. This method allows precise shaping and reduces fabric waste, creating high-quality, well-structured garments.Eco-friendly Interlining is growing. Many brands now use recycled materials, organic fabrics, and biodegradable options. These choices help reduce pollution.

New adhesives in fusible Interlining are safer. They bond without harmful chemicals, making garments healthier for people and the environment. Manufacturers are also using AI to choose the best Interlining for different fabrics. This helps improve efficiency and garment quality.

Conclusion

Interlining is an important part of clothing. It gives support, shape, and strength. Without it, clothes can wrinkle, lose shape, or wear out fast. Different fabrics need different types of Interlining. The right choice makes clothes more comfortable and long-lasting. It also improves the fit and quality.

New technology is improving interlining. Eco-friendly materials help reduce waste. Smart fabrics adjust to temperature. Safer adhesives and AI improve production. Interlining makes clothes look better and last longer. It is used in both casual and formal wear. Knowing its importance helps create better clothing.

FAQs

What Is the Purpose of Interlining?

Interlining adds support, shape, and strength to fabrics, improving durability, comfort, and garment structure.

What Is the Application of Interlining?

Interlining is used in collars, cuffs, waistbands, suits, coats, and structured garments for reinforcement.

Do All Clothes Need a Lining?

No, certain garments need lining for comfort, durability, opacity, or to improve structure.