Introduction

If you know the apparel manufacturing process, you may also see the importance of interlining in the whole process. You use the interlining fabric between two layers of your apparel for a specific purpose. It helps to keep different components of clothing in the desired shape. You may either sew the interlining or fuse it with the chosen fabric.

Generally, interlining is a thick, flexible, and soft fabric. These exceptional supporting components are made from different materials. Some main fabrics are viscose, wool, polyester, nylon, and cotton. Choosing a suitable interlining cloth is not the only thing you also need to focus on some more factors. For example, finishing is performed to improve its properties.

The two most common finishing processes for interlining are Crease-resist and shrink-resist finish. The first prevents the interlining from creasing, while the other prevents it from shrinking. However, these processes are chosen according to the type of interlinings. And each class contains a particular role in the apparel manufacturing process.

Let’s discover the role of fusible interlining in the apparel manufacturing process.

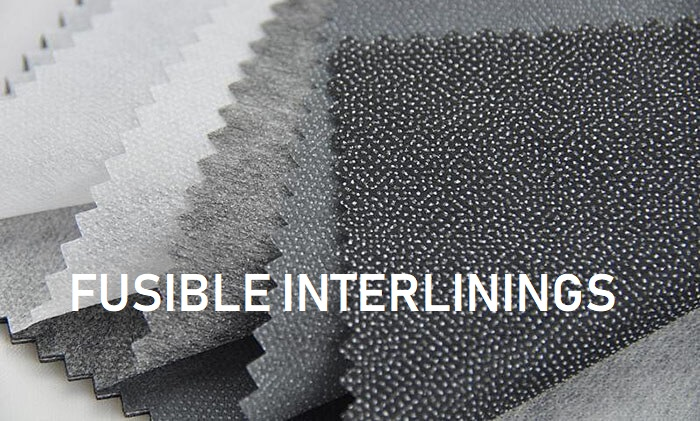

What Is Fusible Interlining?

Fusible interlining is one of the many types of interlining. The best part of knowing about fusible interlining is that it is the most commonly used. As the name suggests, fusible interlining is applied through heat and pressure. You need to apply the pressure and heat for a specific time interval so that it fuses to the garments perfectly.

Fusible interlining requires a particular amount of heat and pressure. Any reduction or increase in both processes can result in damaging the interlining. Another interesting fact is that this interlining is used for apparel manufacturing. Bespoke garments and ready-to-wear garments mostly use fusible interlining.

Some advantages and disadvantages of fusible interlining can make everything more clear. Let’s dig into them.

Advantages

- It helps you give the same outlook of apparel by getting similarities.

- Fusible interlining is most commonly available in the market.

- The process of applying this interlining is straightforward.

- It contains higher productivity.

- Fusible interlining consumes less time as compared to other interlinings.

- It is a cheap option with fantastic performance.

Disadvantages

Although fusible interlining has some fantastic advantages, there are also some downsides. For example, some downsides are:

- You need to take more care when applying pressure and temperature. Any mistake can lead to damaging the fabric as well as interlining.

- High temperature is mainly required in these interlinings.

Applications

- It Supports the shape of your garments.

- Fusible interlining Keeps the rigidity of garments in shape.

- It helps you to fit the garments with your body’s structure.

Types Of Fusible Interlining

There are different types of fusible interlining; each type has its properties. If you classify the fusible interlining based on resin coating, it divides into six main types. These types are:

- Polyethylene coated interlining

- PVC coated interlining

- Polyamide coated interlining

- Polyester coated interlining

- PVA coated interlining

- Polypropylene coated interlining

Role & Importance in Apparel

As mentioned earlier, fusible interlinings help to add structure and support shape to your garments. It is a fact that garments without proper support and shape look weird. Therefore, fusible interlining plays an essential role in gaining the form of attire. In most cases, your garments consist of some crucial regions.

Stabilization of crucial regions in your garments is necessary. Fusible interlining helps you achieve stability and controls those parts of your garments. At the same time, some design features in your garments don’t stand firmly without interlinings. Fusible interlining also helps to strengthen those design parts in your attire.

Using fusible interlining, you may improve the appearance of your finished apparel without affecting the draping quality of the top cloth. Finally, it also helps you to maintain the fresh and crisp look of your apparel. However, when choosing a fusible interlining for your dress, you must ensure its properties match the fabric.

If you choose a fusible interlining with properties different from the base fabric, it may not serve you its purpose. Moreover, you also need to ensure that fusible interlining has a low weight compared to the base fabric. A large weight of interlining may not help you serve your apparel’s supporting purpose.

Which Fusible Interlining Is Most Suitable in the Apparel Industry?

When manufacturers choose a fusible interlining for apparel manufacturing, they consider a few factors. For example, you check the type of fabric and its properties before choosing an interlining. But in most cases, a fusible interlining with low weight and properties matching to cloth is most suitable. As you know, fusible interlining also contains several types.

Despite several fusible interlining types, polyester-coated interlinings are the most suitable. In this type of fusible interlining, you need to use polyester as a resin. And you need these kinds of resins in washable and dry-cleaned garments. The reason behind it is the less water-absorbing nature of fusible interlining. Moreover, it is matchable with most types of garments.

Properties Required for Fusible Interlining

When choosing the right fusible interlining, you must focus on the properties of fusible interlining. Some critical properties required for fusible interlining are:

Tensile & Elastic Properties

Shell fabrics’ elastic and tensile properties play a huge role in stabilizing the parts of the garment. These properties should be compatible with your apparel’s fabric.

Bending

To achieve the correct appearance, your shell fabric and fusible interlining must have suitable bending properties.

Shearing & Surface Properties

When you purchase any apparel, you check its fabric by touching it all over it. You also check the apparel in the try room to see if it fits well with your body. Taking such steps gives you an idea of your apparel. As mentioned previously, you evaluate the textile surface characteristics by visual analysis or touching it.

As a wearer, you may also expect smooth & comfortable surfaces, especially in the wrist points, collars, and cuffs. All those parts that touch your skin should have comfortable fabric, so your skin doesn’t get affected. You should also pay attention to the physical attributes, such as the fabric’s surface friction, thickness, stiffness, and compressibility.

The physical attributes are responsible for affecting the comfort levels of your apparel.

Fabric Handle & Drape Of the Apparel

Fabric handles such as rigidity, plainness, and softness affect the psychological perception of your apparel. However, textiles contain different properties according to their construction. The mechanical and physical properties are necessary to define the fabric.

Necessary Measures Related to Interlining in Apparel Engineering

If you are a garments manufacturer, you need to take some measures to ensure the quality of your garments. These measures include:

Sourcing of Fusible Interlining Fabric

The garments and body fabrics define the kind of interlining you must use. Depending on the stretch, weight, and bonding characteristics, determine the characteristics of interlining. The final shape and level of stabilization determine the type of interlining for your apparel.

Marking The Garments Parts

You should mark the parts that require interlining in your apparel. Then you have to prepare a pattern that matches the shape of those parts. The use of fusible interlining may depend on your garments’ comfortable and luxurious finish.

Methods To Fuse Interlining

The method chosen to use fusible interlining defines the stability of your apparel. For example, some interlinings fuse better with steam, while others fuse better with the help of dry iron. You need to set the parameters of the machine properly to ensure perfect fusing.

Type Of Machine

There are two types of machines that are used for fusible interlining applications. These two types are:

Flatbed type.

- You have to keep the fusible interlining on a flat surface to fuse it with the garment.

- Then, you have to press the upper surface of the interlining.

- This method is preferred when applying the interlining to exclusive apparel.

Roller-type machine/ Continuous moving belt.

- Uses more power

- More expensive equipment

- Saves energy by using steam.

The second one is the most commonly used machine for fusible interlining.

Preventive & Defective Measures

Make sure you take preventive measures to avoid defects in the final interlining. For example, don’t use pressure or temperature more than the recommended time interval. Take special care when applying interlining on your fabric. Sometimes, color change also occurs in the bonding process. Or it can also result in the accumulation of static charge, rips in interlining, and color patches.

Conclusion

The role of fusible interlining is clear from the above discussion. Fusible interlining should be a priority if you want to attain the shape and support for your apparel. But you also need to focus on the facts, such as choosing the right type and quality of fusible interlining. Moreover, selecting the proper manufacturer also plays an important role.