Introduction

Interlining is an essential part of the manufacturing of garments. And you must know that different types of interlining exist. You must consider multiple factors when planning to use an interlining for your fabric. And some of those factors are advantages, disadvantages, quality, properties, preparation technique, and much more.

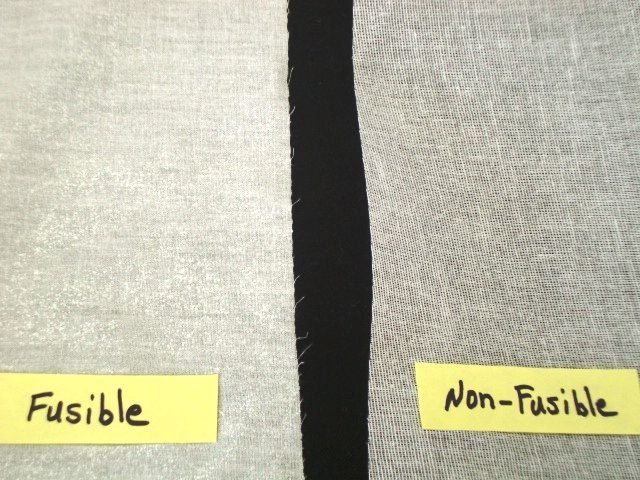

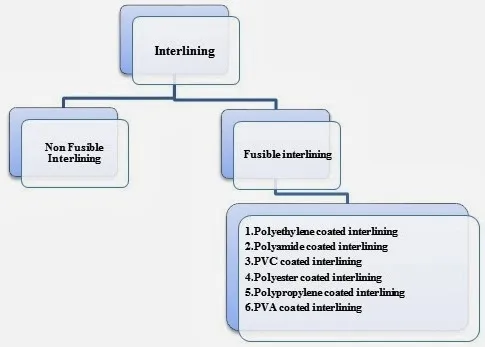

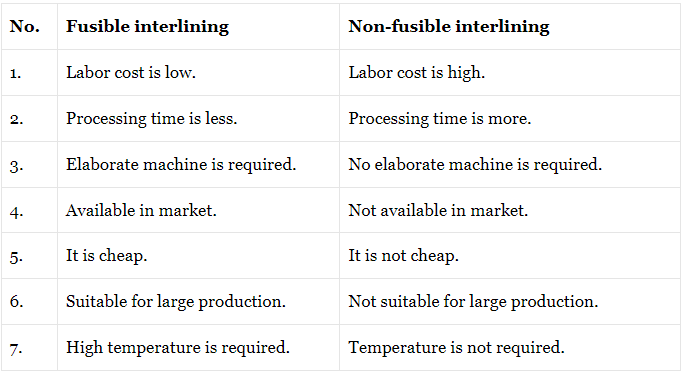

Fusible interlining and non-fusible interlinings are the two most common types of interlining. Most manufacturers use these interlinings in the garments, but a wrong interlining can waste time. For example, knowing the pros, cons, and other differences can save you time.

So how to avoid this situation? Let’s dig into some factors differentiating between fusible and nonfusible interlining.

What Is a Fusible Interlining?

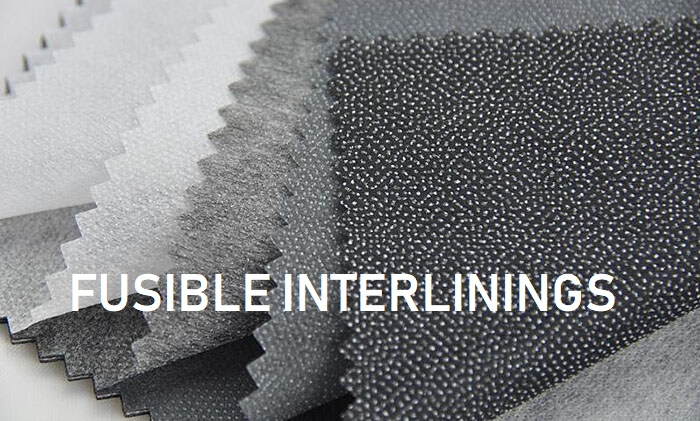

Fusible interlining is one of the most common types used in garment manufacturing. It aims to support your clothes and maintain the shape of garments. You differentiate the fusible interlining from other interlinings in terms of how you apply it. There is glue on both sides of the interlining. The hot melt glue aims to strengthen the stress points.

Let’s explore some of its advantages, disadvantages, and applications.

Advantages

- The first and most important advantage is that fusible interlining is very easy to apply. You don’t have to deal with extra complications.

- Secondly, it gives the same look as that apparel.

- Fusible interlining is readily available in the market, unlike other interlinings.

- Fusible interlining is also known for its high productivity.

- The best part to know is that fusible interlining consumes less time.

- You can afford it and manufacture garments in bulk amounts at low prices.

- It is also known for its the high-performance.

Disadvantages

- One of the most common disadvantages is that fusible interlining usually requires a high temperature.

- Secondly, you need to apply appropriate pressure. Otherwise, it may not stick to something other than the fabric properly.

- Fusible interlining requires special care when you apply it to your fabric. A little mistake can put it in the wrong place or direction.

Applications

Regarding applications, fusible interlining is equally suitable for all apparel manufacturing. Bespoke and ready-to-wear garments are the two most common applications of fusible interlining.

Preparation Technique

You must be aware that each interlining type has different preparation techniques. You may not use other processes for every interlining. Otherwise, you may end up wasting money. Moreover, applying the same method can also damage your garments. So let’s explore the proper technique for fusible interlining.

First, it is to be sure that fusible interlining is applied between two layers of fabric. And to achieve a smooth application, you must use a particular amount of heat and pressure. It is better to ask your manufacturer about the instructions regarding the required heat and pressure. Here is the method to prepare fusible interlining.

Base Fabric

First, you need a base fabric that will help you prepare an interlining for your garments. There are so many kinds of base fabric in the market, but some most common types are listed below:

- Non-woven fabric

- Knitted fabric

- Woven fabric, etc.

In most cases, you can see that manufacturers use woven fabric as a base fabric in garment manufacturing.

Resin Coating

Resin coating is applied on the chosen base fabric. You must know there are different methods to apply resin coating on your base fabric. The five most common ways to apply Resin coating are listed below:

Scatter coating

Dry-dot coating

Paste interlining

Film coating

Emulsion coating.

You must know that whichever method you choose will affect the properties of your fusible interlining. Therefore, you must study how the technique will affect the fusible interlining.

Drying

Once the resin coating method is done, you must apply heat over the fusible interlining. Once it is done, you have to go for drying, and your fusible interlining is ready.

What Is a Non-fusible Interlining?

Non-fusible interlining is also known as sew-in interlining. This interlining needs to be sewn between two layers of fabric. And the important thing to note is that you don’t need to apply heat and pressure in a fusible interlining.

You must know that a non-fusible interlining cannot be used in most garments like fusible interlining. It is only used in some particular kinds of dresses.

In other words, you can also say that a non-fusible interlining is applied without any chemical bonding.

About 90% of garments manufacturing requires fusible interlining, while the rest requires non-fusible interlining.

Advantages

- Non-fusible interlinings are highly helpful in flame-retardant garments.

- You can stitch them using an easy technique.

- You don’t need an elaborate machine to use a non-fusible interlining.

Disadvantages

- One of the main reasons that non-fusible interlining is not used in most garments is its poor quality.

- Non fusible interlining is not considered the right choice for manufacturing garments in bulk amounts.

- You might need help finding it in the market.

- Nonfusible interlining requires more time as compared to fusible interlining.

- There is a high labor cost and workload in using a nonfusible interlining.

Applications

Fabrics that require non-fusible interlining are listed below:

georgette,

silk,

chiffon,

crepe and seersucker

transparent and delicate material,

Preparation Technique

Attaching a non-fusible interlining is very different from attaching a fusible interlining. To make the final piece, you must go through various steps, such as pattern making, cutting with seam allowances, and stitching. Let’s check out the preparation technique for your non-fusible interlining.

Base Fabric

In most non-fusible interlinings, you must choose a base fabric like fusible interlinings. But the nature of base fabric varies as you have to choose nonwoven or knitted fabrics.

Adhesive Application

In the adhesives applications, you have to choose starchy material for non-fusible interlining. Starch materials are used as adhesives.

Drying

To fix the adhesives on the base fabric, you need to perform drying. And finally, your non-fusible interlining is ready.

Conclusion

After reading this article, you must know about the non-fusible and fusible interlinings. These interlinings differ in advantages, disadvantages, applications, and many other factors. Consult an expert before applying any interlining in your garments.

Contact Us now if you want a high-quality interlining or consultation regarding interlining for your garments.