Introduction

Interlining is considered an important trim in the manufacturing of shirts. The reason is that interlining can fulfill functional and aesthetic aspects. However, garments manufacturers may need to realize the importance of the right interlining for your shirts. Even though the right interlining can do wonders for a shirt, they don’t take it seriously.

If interlining is the most crucial trim, fusing is the essential process in shirt manufacturing. Most manufacturers only intend to insert a piece of fabric between two layers of your shirts.

However, they forget that there is a need to consider multiple factors when performing the process. The best interlining for your shirts is that one that improves the quality of your shirts.

But how do you know that the particular interlining can do wonders for your shirt? This is very easy to figure out since you only need to check the properties of interlining, shirt, and requirements. This article explains some of the most common shirts and their requirements for interlining. This is something that will help you get the right interlining for your shirts.

However, before moving forward, we suppose you might be a beginner. So, we will start with some basics of interlining and its role in shirt manufacturing. So what are you waiting for? Let’s continue reading and get the best interlining for your shirt.

What Is Best Interlining & Its Role in Shirts Production?

The term “interlining” is not new if you are a garment manufacturer or a regular buyer. But if there is another case, you must know interlining plays a good role in maintaining your shirt’s shape. You can also say that is one of the essential aspects of shirt manufacturing. If you want your shirt to perfectly f your body shape, you must ensure it has interlining.

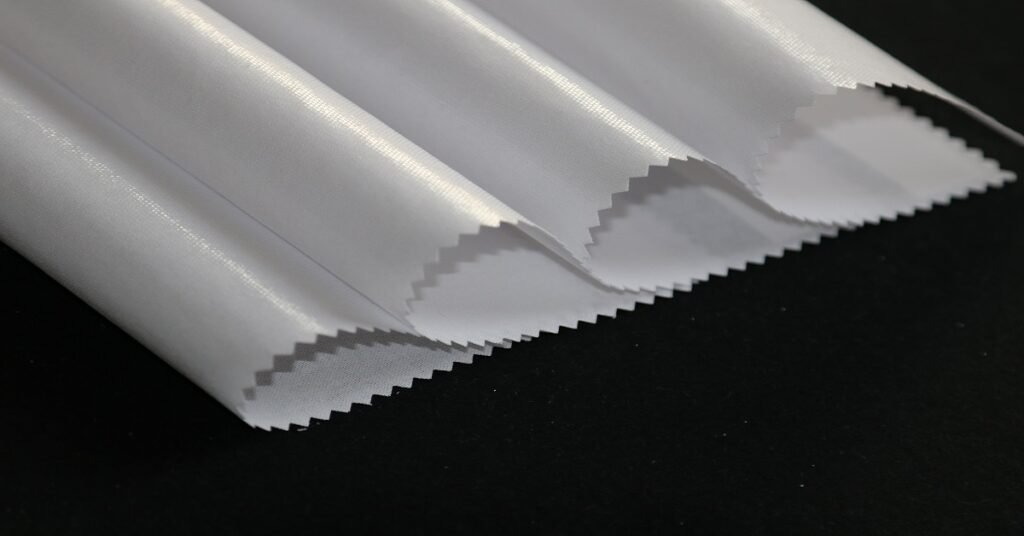

Your shirts have two layers; internal and external layers. The manufacturers insert interlining between these two layers. The purpose is to maintain the shape of your shirts. Interlining acts like a skeleton to ensure the formation of shirts. However, you must know that this interlining skeleton also comes in different types.

It is interesting to note that interlining comes in different qualities, just like other types. And you also need to know that interlining must be added to specific parts of the shirts. For example, collars, button packets, waistbands, and cuffs are the most sensitive parts that act as supporting body parts.

The Role Of The Best Interlining In Shirts Production

- It adds a firm layer to your shirts.

- It prevents the creasing in your shirts but only when you purchase a high-quality interlining.

- Interlining also helps to avoid seating in the shirts. A silk organza interlining works best in this case.

- You can add drape and density to your shirts by using interlining.

- These interlinings can drastically improve the quality of your fabrics and prevent ridges.

What Interlining Solutions to Consider in Shirt Manufacturing?

Interlining is any fabric inserted between two materials to give a more structured and firm look. As mentioned earlier, interlinings are used in the detailed areas of your shirts. Moreover, they also help the garment components wh extra wearing stress. The most common parts that require interlining are buttons, waistbands, pockets, necklines, pocket flaps, cuffs, and collars.

It is also important to note that there are two types of interlining shirts. Those types are sew-in interlinings and fusible interlinings. The first type is stitched between two pieces of fabric. On the other hand, the second type is fused by using a specific amount of heat and pressure. You must know that 90% of the clothes are made from non-sew-in or fusible interlinings.

When an interlining is not sewn or fused correctly, it results in multiple problems. Those problems are known as strike back, bubbling, and strikethrough. Bubbling is localized delamination, while strikethrough is when glue penetrates through your fabric.

The strike-back condition refers to the situation when interlining glue penetrates the back of the interlining.

From the above discussion, choosing the right type of interlining matters in shirt production. At the same time, selecting the best interlining can be tedious. You must ensure that the properties of your fabric match the properties of interlining. For example, the shrinkage level of both parts should be the same. Otherwise, it may result in above mentioned faults.

Classic Dress Shirts

You must know the fact that classic shirts require more stiffness than other shirts. If you are a person who follows fashion and trends, you must know the upcoming big trend in classic shirts.

People demand more comfortable and stiff collars in their classic shirts. It is essential to use an interlining made from 100% cotton to ensure these properties.

The 100% cotton interlining contains an amazing level of stiffness. As a result, it doesn’t let the collar distort easily. The reason is that it exerts maximum control on shape retention and shrinkage.

If you want to achieve an aesthetic feel, you must look for lightweight cotton fusible interlining wh a soft touch. It can be a perfect solution to fulfill the aesthetic aspect of your shirts.

Another solution for your classic shirts is to use interlinings made from natural fibers. Some examples are veg, wool, and silk. But these interlinings are not known for their soft feel and handle.

Jersey Shirts

If you are an office-goer, you must know the importance of stretchable and soft collar combinations. At the same time, you may also prefer ease of movement when wearing your jersey shirt. Therefore, new fabric constructions are introduced every day in the market. Plain stretch, jersey, and knit fabrics are setting new standards and becoming the current trend for jersey shirts.

Simply put, you need to ensure more stretchability in jersey shirts and hence choose the interlining accordingly. You must use bi-elastic interlinings for jersey shirts to ensure a higher stretchability.

Nylon & Polyester Shirts

You must know the fact that different fabrics in the market have different properties. It is essential to consider those properties before you perform any treatment on them. The fabric made from nylon gives a super soft feel. At the same time, it is the most heat-sensitive fabric. This is something that makes the fusing process very difficult.

You may not get the desired results from cotton interlining. The reason is that it has a higher thermal shrinkage. Therefore, you must choose an interlining fabric that can be fused at a lower heat. You can also choose an interlining fabric from the Freudenberg 63XX range. It can give you a better bond strength and can be fused at a low temperature.

Uniform Shirts

is a fact that uniform shirts require more washability than regular shirts. Since these shirts are used on a daily basis, therefore, more washability is required for them. However, when you use bad interlining in uniform shirts can cause a large number of problems. One of the most common problems is bubbling, which you can find after a certain number of washes.

In this case, you have to select an interlining that comes wh good quality. Normal cotton interlining might not be usable for you. Therefore, you must choose a cotton interlining wh better quality and properties.

You can also look for uniform shirts interlining in the Freudenberg 68XX range. The reason is that millions of shirts are tested why this type of interlining.

You can also consult your shirt manufacturer to suggest the right type of interlining.

How to Select Right Interlining For Your Shirts?

Now that you have learned about the characteristics of different shirts, this task has become easier for you. You have to keep in mind a few important factors if you want to choose the best interlining for your shirts. Here are some key points that can make this job easier for you.

- Check the properties of your fabric and then select an interlining accordingly.

- Choose an interlining that must have a lighter weight than your targeted fabric.

- Your interlining fabric should have similar care instructions as that of your shirts.

- The interlining fabric must have enough level of insulation.

- Ask your manufacturer for some good advice on choosing the right interlining.

Conclusion

You must know the fact that the best interlining is the one that perfectly supports your body. Not only this, but you must have an interlining that plays a role in improving the quality of fabrics. If you are looking for a high-quality interlining fabric, you must contact us now to get a quote. Our manufacturers are always there to give you excellent advice for your garments.