Introduction

Interlining reinforces and supports various items such as clothing, curtains, and upholstery. It is placed between the main fabric and the lining, hence the name interlining. Interlining can be made of various materials, including cotton, wool, flannel, fusible interfacing, and others, each with unique properties.

In clothing, interlining fabric provides warmth and stability to outerwear such as jackets and coats. In curtains and draperies, it adds fullness and prevents wrinkles, providing a more polished and finished appearance. In upholstery, interlining is used to provide a cushioning effect and increase the durability of the furniture.

We can sew in or attach an interlining using a fusible bonding process. It is a heat-activated adhesive that bonds the interlining to the main fabric.

The specific needs of the item, such as the type of fabric, the weight of the material, and the desired effect, determine the type of interlining used. Whether you’re a DIY enthusiast or a professional in the fashion, textiles, or home decor industries, understanding the role and benefits of interlining can be a valuable asset in your outer fabric.

Let’s check out what is interlining application for your garment fabric.

What Is Interlining Beneficial For?

Interlining offers several advantages in various applications, including clothing, curtains, and upholstery. Some of the critical benefits of interlining are:

Reinforcement and stability: Interlining provides additional support and stability to the main fabric, increasing the item’s durability.

Insulation: Interlining can provide warmth to clothing, making it suitable for outerwear.

Fullness and Wrinkle Prevention: In curtains and draperies, an interlining adds fullness and prevents wrinkles, providing a more polished and finished appearance.

Cushioning Effect: In upholstery, interlining provides a cushioning effect, increasing the comfort and durability of the furniture.

Customization: Interlining can be chosen based on the specific needs of the item, such as the type of fabric, weight, and desired effect.

Overall, it is essential in creating various finished products, offering reinforcement, insulation, fullness, and cushioning to enhance their appearance and functionality.

What are The Disadvantages Of Interlining?

Although offering several benefits, interlining can also have disadvantages in specific applications. Some of the drawbacks of interlining include the following:

Increased Cost: Interlining can add to the item’s overall cost, as it is an additional material that needs to be purchased and incorporated into the final product.

Weight: Interlining can add weight to the item, making it less comfortable to wear or use.

Difficulty in Sewing: Interlining can be challenging, especially for inexperienced people. Incorrectly sewing interlining can result in uneven or puckering fabric.

Heat Sensitivity: Some interlining materials can be heat-sensitive, making it necessary to handle them carefully when using heat-activated bonding processes.

Incompatibility with Certain Fabrics: Interlining may only be suitable for some fabrics, as some may be too delicate or lightweight to support them.

What Is Interlining Usage in Garments?

Here are some reasons that we use interlining in Garments.

Warmth

Interlining is a great insulator, making it an excellent choice for adding warmth to jackets, coats, and other outerwear. It is essential during the colder months to stay warm and protected from the elements.

Structure and Support

Interlining provides additional structure and support to the main fabric, making it ideal for reinforcing heavy and bulky fabrics. It helps prevent the garment from losing shape over time and adds to its overall durability.

Customization

Interlining can be customized based on the specific needs of the garment. For example, you can choose lightweight and breathable interlining for summer jackets or a heavier, more insulating material for winter coats.

Improved Appearance

The interlining gives a garment a more polished and finished appearance. For example, interlining can add fullness to a jacket, making it look more substantial and less flimsy.

Which Areas of Garments Mostly Require Interlining?

Interlining is used in various areas of garments to provide support, structure, and insulation. Some of the areas in which interlining is used chiefly include:

Outerwear

Interlining is widely used in jackets, coats, and other types of outerwear to provide warmth and structure.

Collars and Cuffs

Interlining is often used in collars and cuffs to provide support and prevent sagging over time.

Shoulders

Interlining is used in the shoulder area to provide additional structure and support, especially in heavy jackets and coats.

Chest and Lapel Areas

Interlining is used in the chest and lapel areas to provide additional fullness, structure, and support.

Trousers and Skirts

Interlining is sometimes used in trousers and skirts to provide fullness and support, particularly in heavier or more structured garments.

Overall, interlining is used in various areas of garments to provide additional support, insulation, and structure. The choice of interlining will depend on the specific requirements of the garment. Some examples are the type of fabric, the weight of the interlining, and the desired appearance.

What Are Some Common Types of Interlining Available in the Market?

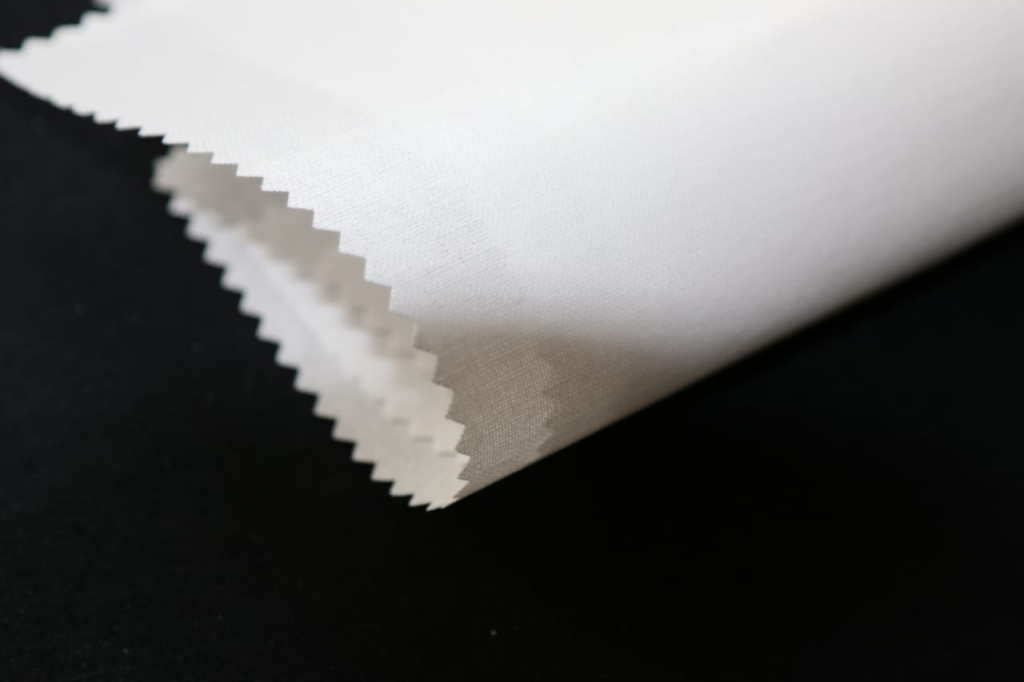

Fusible Interlining:

Fusible interlining has a heat-activated adhesive on one side, allowing it to bond to the main fabric. This type of interlining is easy to work with and provides a stable and durable bond. It is ideal for heavier fabrics and outerwear. Depending on the desired effect, the fusible interlining can be made from various materials, such as polyester, cotton, or wool.

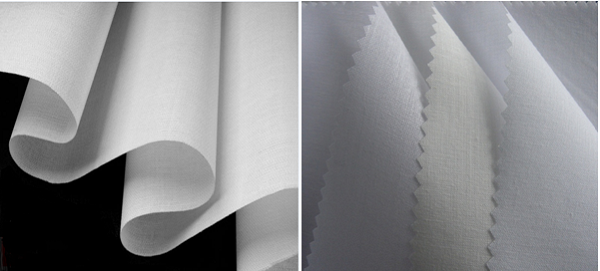

Non-Fusible Interlining:

Non-fusible interlining is a type of interlining that does not have a heat-activated adhesive. Instead, it is sewn to the main fabric. This type of interlining is ideal for delicate fabrics that cannot be exposed to heat, such as silk or chiffon. Non-fusible interlining provides structure and stability to the main fabric and is often used in the production of tailored garments, such as jackets and coats.

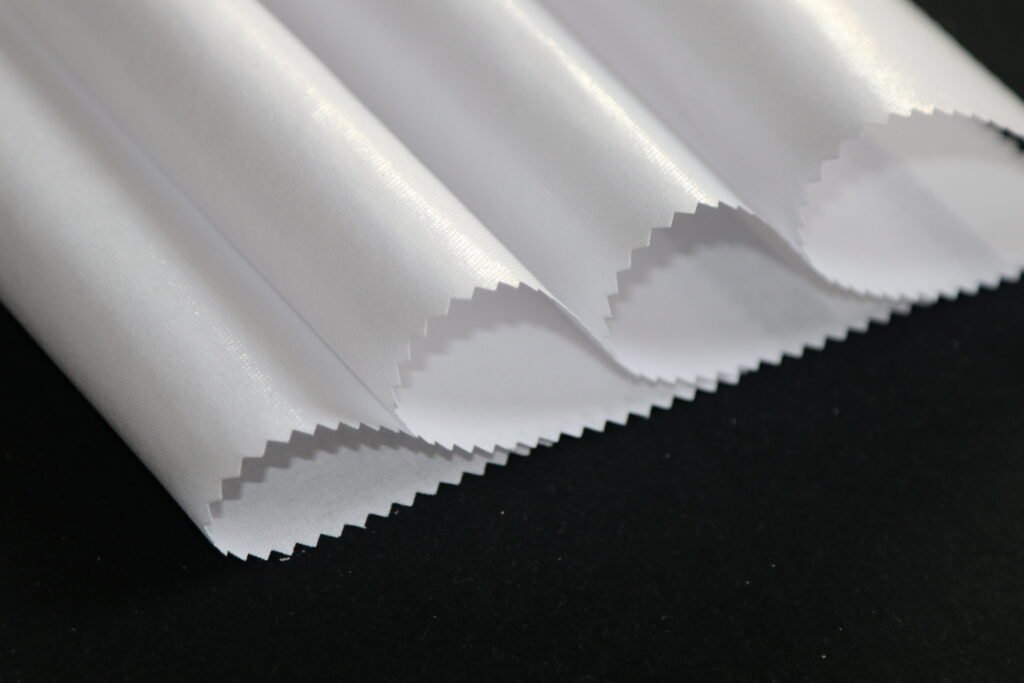

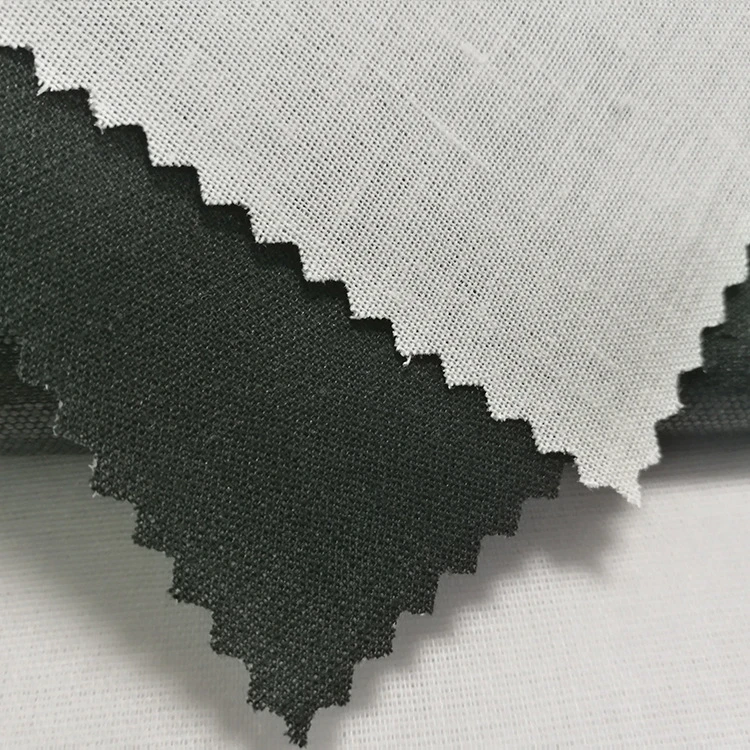

Woven Interlining:

Woven interlining is made from woven fabric, such as cotton or polyester. This type of interlining provides structure and stability to the main fabric and is ideal for heavier garments, such as jackets, coats, and trousers. Woven interlining can be made from various materials, such as wool or polyester, depending on the desired effect.

Knitted Interlining:

Knitted interlining is a type of interlining that is made from knitted fabric, such as fleece or jersey. This interlining is ideal for adding warmth and insulation to garments and providing a softer, more flexible feel. Knitted interlining is often used in the production of winterwear, such as jackets, coats, and vests.

Hair Interlining:

Hair interlining is made from animal hair, such as rabbit or horsehair. This type of interlining is ideal for adding fullness and support to the main fabric, especially in areas that require a lot of structure, such as collars and cuffs. Hair interlining is often used to produce tailored garments like jackets and coats.

What Safety Measures to Take When Using an Interlining?

While interlining is essential in many clothing and textile products, it is important to take safety measures. Let’s discuss some safety measures that should be taken when using an interlining.

Choose the Right Interlining:

The first step in ensuring safety when using an interlining is choosing the right type for the specific project. Different types of interlining have different properties and benefits, and it is essential to choose the right one to ensure that the final product is safe and of high quality.

Use Proper Equipment:

When using an interlining, it is essential to use proper equipment, such as a sewing machine and iron. It helps to ensure that the interlining is securely attached to the main fabric. Using the right equipment will also help to prevent accidents and injuries, such as burns or cuts.

Follow Safety Guidelines:

It is essential to follow safety guidelines when using an interlining, especially when working with heat-activated adhesives or other hazardous materials. It may include wearing gloves, protective eyewear, and carefully following the manufacturer’s instructions.

When gluing hot melt adhesive interlining, pay attention to setting the temperature, pressure, time, HDPE glue, and temperature 160-180 degrees Celsius. Here are the standards that you must follow:

the time between 12 to 18 seconds, pressure 3.5kg, PA, PES glue, temperature between 130-140 degrees Celsius, time 12 to 15 seconds, pressure 2kg.

Test the Interlining Before Use:

Before using an interlining, it is essential to test it to ensure that it is safe and appropriate for the specific project. It may involve testing the interlining’s heat resistance, colorfastness, and durability.

Store Interlining Safely:

When not in use, it is essential to store interlining safely and securely, away from heat sources and flammable materials. It will help to prevent accidents and ensure that the interlining remains in good condition for future use.

Final Thoughts

In conclusion, interlining is a versatile and essential material used in many industries, including clothing and textile, aerospace, and automotive. It adds strength, stability, and insulation to various products, making them more durable and comfortable. With the increasing demand for high-quality products, interlining has become a critical manufacturing component.

Whether it’s used in the creation of clothing, aircraft components, or automobile interiors, interlining ensures that the final product meets the necessary standards and delivers the desired results. From improving the overall structure of a product to providing thermal protection, interlining has proven to be a valuable material with a wide range of applications.