Introduction

Interlining plays a substantial role in the manufacturing of your garments. You must use good-quality interlining when you want other people to prioritize your brand. But at the same time, choosing the right type of interlining is also essential. However, some people don’t understand why you use interlining for your fabrics. It is what you will learn in this article.

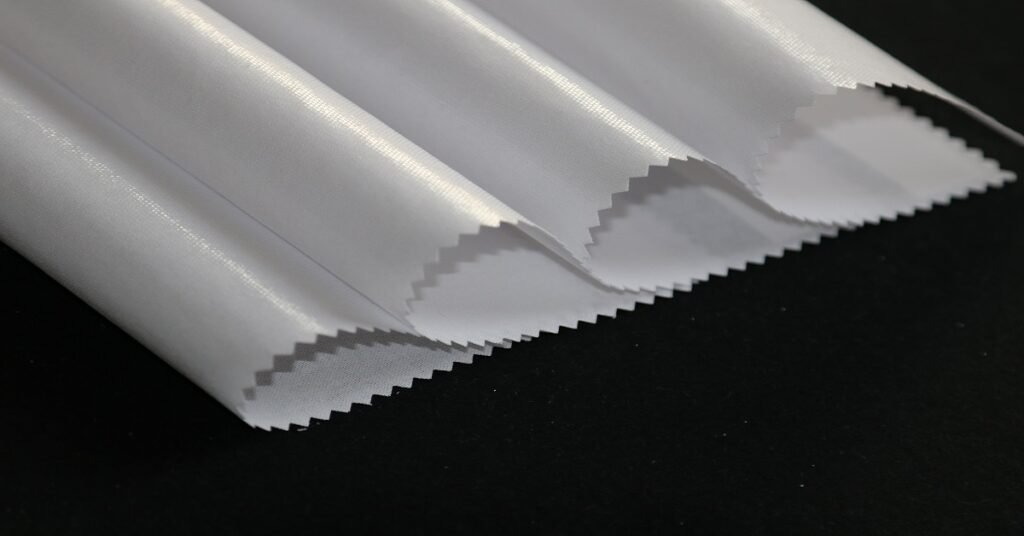

According to some expert garments manufacturers, interlining is like magic that supports the garments’ shape. You can’t see it with the naked eye, but the difference in the fabric is clear when it is not stitched with a cloth. It means the manufacturers use this magical tool, interlining, for a specific reason. This soft, flexible, and thick fabric carries a lot of importance.

Before proceeding further, you must note that interlining is also named interfacing. Therefore, you should never confuse these two terms together. So let’s begin to understand what it does to your garments. Please continue reading.

What Is an Interlining?

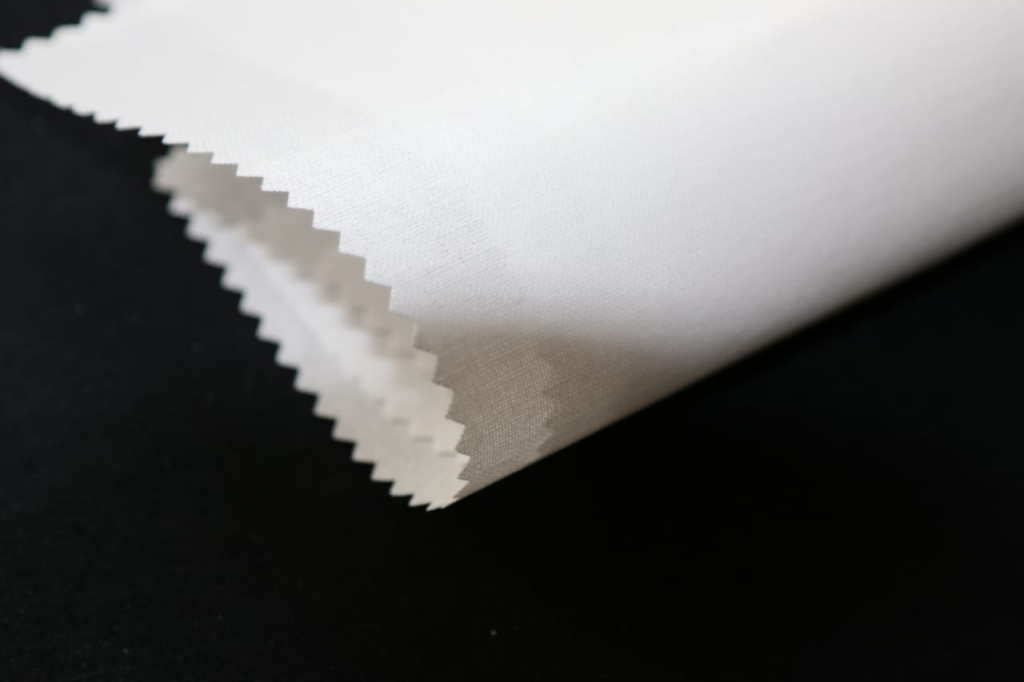

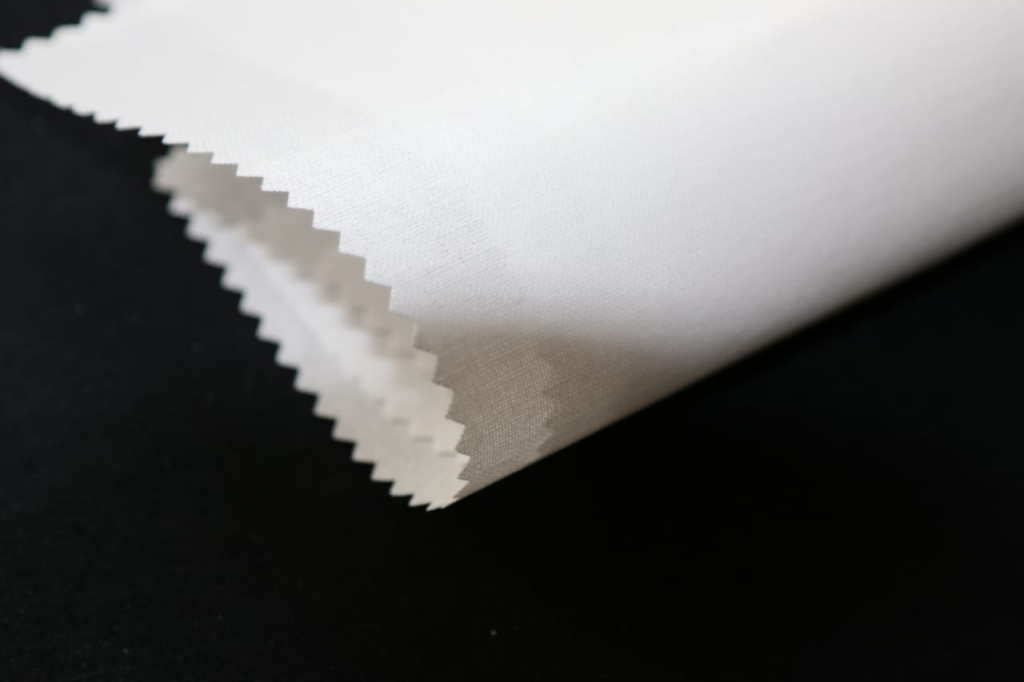

Before knowing the role of interlining for our fabrics, it is essential to understand interlining. It will make everything clear from the beginning. If you ever notice your fabrics, you can feel a third layer between the internal and outer layers. This is what you call the interlining.

But sometimes, you can see the excellent shape of your fabrics but not feel a third layer between its layers.

You may think that there is no interlining present. But the case is fascinating here. But How?

Well, Interlining comes in different forms. When you use a fusible interlining, it fuses with your garments without appearing as a third layer. But when you use a non-fusible or sew-in interlining, you can feel the third layer between two layers of your fabric.

Now when it comes to using an interlining, you use interlining to support, reinforce, and control areas of your garments. It helps your garments to retain their actual shape. You can apply it either by sewing or by bonding.

But in most cases, the bonding method is used. It is important to note that interlining fabrics are manufactured from different materials you choose according to various factors.

Why Do You Use Interlining?

As mentioned earlier, you use interlining to retain the structure or shape of your garments. In simple words, interlining is also used for quality assurance or quality control in your attire.

When you need more body or structure to your garments, interlinings play a magical role. Cuffs, waistbands, buttons plackets, and collars are some most targeted parts to use for interlining.

Using interlining is one thing. But considering the durability of interlining is another thing to know. Only a highly durable interlining can help you achieve proper structure and shape control for your garments. You can maintain the rigidity of your garments and fit them to your body structure only with the help of interlining.

Interlining also plays a role in extending the lifespan of your fabrics. Moreover, you can improve the hand feel and aesthetic of your clothes by using fusible interlining.

What Happens if You Don’t Use Interlining in Garments?

If you are a garments lover, you must have noticed that some parts of your garments are rigid. Some of these parts are cuffs, collars, and waistbands. They carry more rigidity than the rest of the fabric. Manufacturers of garments achieve this support or rigidity only with the help of interlinings. Now from these examples, you must know why manufacturers use interlining.

A shirt or attire stitched without an interlining carries no shape at all. You can also reinforce stitches by using fusible interlining. It can help to support more pressure on the body. In simple words, garments without an interlining are low-quality interlining. So when you don’t use an interlining in your garments, it also reduces their quality.

Let’s take another example. You must have seen people with nicely toned bodies and those who don’t have nicely toned bodies. The difference between the two is noticeable.

The same case happens with an interlining. A dress without an interlining doesn’t have a rigid shape. On the other hand, a dress stitched with an interlining is more like a nicely toned body.

How Should You Select Interlining Fabric?

Whenever you go to the market to purchase something, you always think about various factors. For example, you think of size, color, quality, price, and other factors. So when you are choosing an interlining, you think about some similar characteristics. So when you are selecting an interlining fabric for your next sewing project, you follow particular criteria.

The criteria for choosing an interlining fabric are below:

- The interlining fabric should have lightweight. According to most experts, an interlining fabric should weigh less than the targeted fabric. It will help you lower the bulk of the material of your garment.

- Manufacturers recommend choosing an interlining fabric with similar care instructions to the outer fabric. If the care instruction varies for both materials, it can highly affect the quality of your garments and result in low-quality attire.

- Thirdly, you should cut the interlining to the same grainline as the outer fabric.

- The interlining is applied in such a way that it is not see-through. Therefore, you should choose an interlining fabric that doesn’t reveal the interlining from the outside.

- The interlining fabric should be manageable for the outer fabric.

- Lastly, the interlining fabric should have enough insulation without being too stiff or thick.

Some most popular interlining fabrics are listed below:

- Tricot knit interlining fabric

- Fiber webs

- Fleece

- Batting or wadding

- Flannel

- Cotton Fabrics

- Hair canvas

- Wool

- Buckram

- Rayon Challis

Can You Use Any Type of Interfacing With Your Fabric?

You must note different fabrics require different interlinings. You must consider various factors before using an interlining garment. The properties of garments are essential to consider when choosing interlining or interfacing. There is also a selection criterion to select a particular type of interlining with your specific fabric.

It is interesting to note that there are different market interlining types. The classes vary based on the fabrics used for interlining. It indicates that each interlining carries other properties. There are a few common types of interlining and its types. Note that the kinds of interlining are categorized based on some factors. These types, according to application, are:

Fusible Interlining

It is one of the most commonly used interlining in garment manufacturing. Like other types of interlining, fusible interlining also supports your garment structure. The name fusible comes from the fact that you fuse this interlining with your garments. The best part about it is the ease of application. You can’t feel this type of interlining as a third layer.

When you want to know the interlining type in your garments, you only need to perform a straightforward test. You have to grab the cloth from both sides and check if you feel a third layer inside it. If there is no third layer, fusible interlining is used. At the same time, the third layer indicates that non-fusible or sew-in interlining is used.

Fusible interlining is the right choice if you want to stabilize irregular patterns or delicate fabrics. It is interesting to note that 90% of the garments are manufactured from fusible interlining.

Non-fusible Interlining / Sew-in Interlining

Nonfusible interlining is one you can’t apply by the fusing process. This is very clear from the name “non-fusible.” Instead, you stitch this interlining through the sewing process. About 10% of the garments are manufactured from non-fusible interlining. The fact is that this interlining requires special care, and it is not as cheap as fusible interlining.

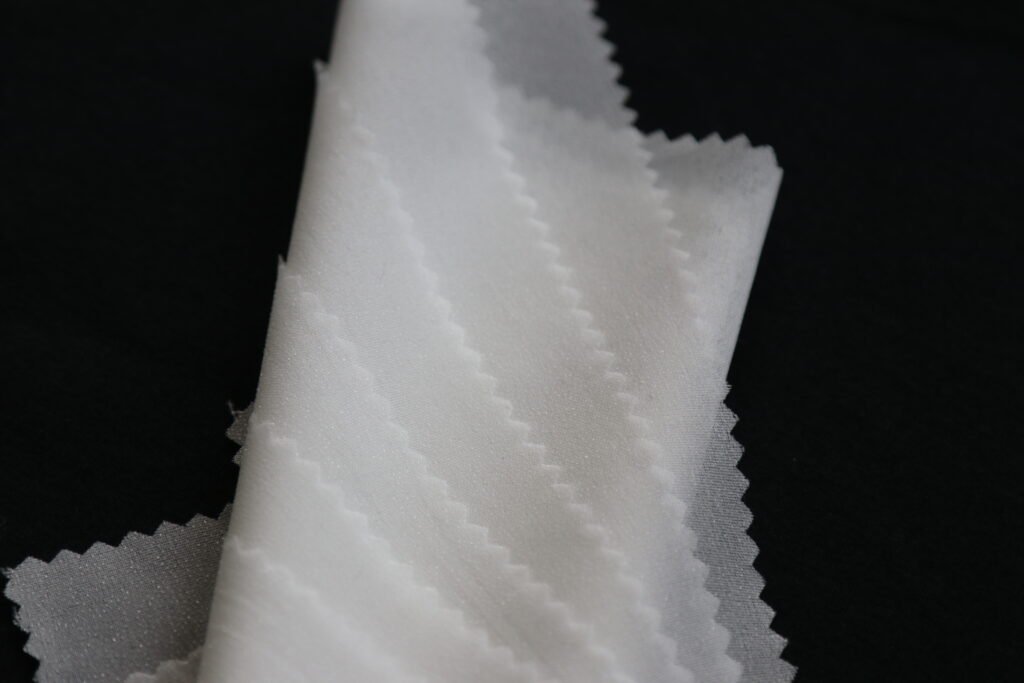

Interlining Types According To the Fabric Structure

- Woven Interlining

- Non-woven Interlining

- Knits Interlining

Conclusion

Interlining does wonders for your garments. Famous garment manufacturers use high-quality interlining that makes them popular among people. Simply put, interlining puts life into your clothes. It increases the durability and lifespan and maintains the shape of your garments. You can say that interlining is a magical tool to support and structure your garments.

Interlining is a fantastic fabric to use in your garments, but still, there is one thing to consider. You must choose the right quality and type of interlining. Just like that, the weight of your interlining also plays a good role. If you are a garment supplier or manufacturer, you must use interlining in bulk amounts.

Contact Us now if you want good-quality interlining within an affordable price range.