Introduction

Have you ever encountered the frustrating sight of bubbling or wrinkling on your favorite garments after washing? If so, you might be dealing with an issue related to fusible interlining. This mysterious problem can leave you puzzled and wondering why it’s happening. In this blog post, we’ll delve into the root causes of why fusible interlining bubbles after washing.

Whether you’re a garment manufacturer, a fashion enthusiast, or just someone curious about textiles, understanding these factors is essential. Join us as we unravel the secrets behind this phenomenon and explore preventive measures to ensure your garments stay pristine after every wash.

How Fusible Interlining Works

Fusible Interlining Application Process

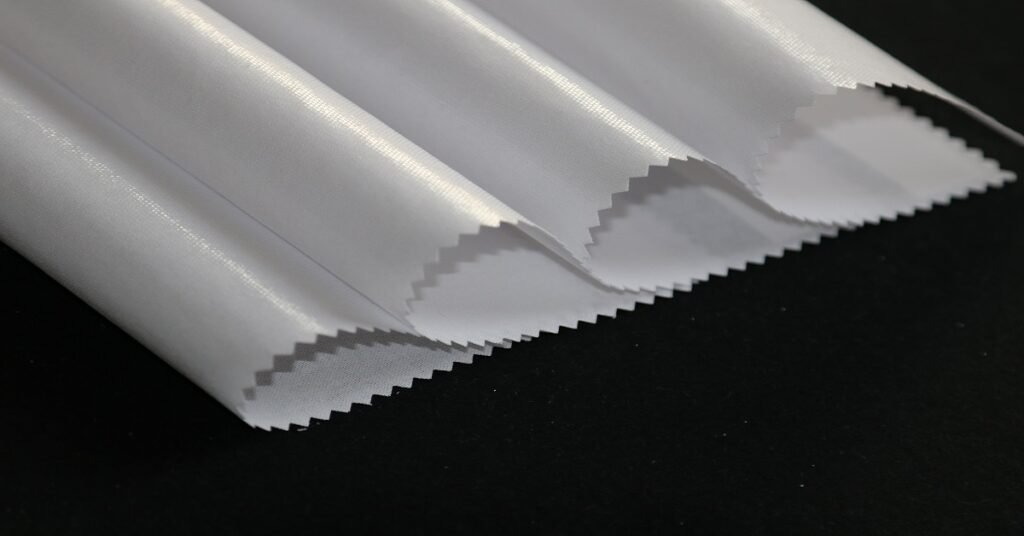

When you purchase a garment with a smooth and structured appearance, chances are it has fusible interlining hidden within its layers. Fusible interlining is a specialized fabric, often made from polyester or a blend of fibers, with an adhesive coating on one side.

The application process involves placing this adhesive-coated side against the wrong side of the garment fabric, creating a sandwich-like structure. Once in position, heat and pressure are applied, activating the adhesive and bonding the interlining to the material.

Bonding Mechanism Between Interlining and Fabric

The magic behind fusible interlining lies in its bonding mechanism with the fabric. As the heat is applied, the adhesive on the interlining melts, allowing it to penetrate the fabric’s fibers. When the heat source is removed, the adhesive cools and solidifies, forming a strong bond between the two layers.

This fusion significantly enhances the fabric’s stability and shape retention, supporting collars, cuffs, and other areas requiring structure in garments.

Role of Heat and Pressure in the Bonding Process

Heat and pressure are vital in ensuring a successful bonding process between the interlining and the fabric. The temperature, time of application, and pressure exerted must be carefully controlled to achieve optimal results. Too little heat or pressure may result in inadequate bonding, leading to bubbling or wrinkling after washing.

Conversely, excessive heat or pressure could damage the fabric or interlining, compromising the overall quality of the garment. Thus, a delicate balance is essential in achieving a well-bonded fusible interlining that withstands the test of time and washing.

Factors Influencing Bubbling

Quality of Fusible Interlining

Choosing the right type of fusible interlining is crucial in preventing bubbling issues. Opt for interlinings specifically designed for the fabric and garment you work with. Using the wrong type can result in poor adhesion and bubbling after washing.

Additionally, the quality of the interlining matters significantly. High-quality interlinings from reputable suppliers are less likely to cause bubbling, as they have a consistent and reliable adhesive coating.

Fabric Type and Composition

The fabric you use in conjunction with the fusible interlining also plays a pivotal role in preventing bubbling. Ensure that the interlining and fabric are compatible, both in terms of fiber content and construction.

Different fabrics may have different melting points, shrinkage rates, and structural characteristics, affecting the bonding process. Consider the fabric’s weave and weight, as thicker fabrics might require different interlining types to avoid bubbling issues.

Washing and Care Instructions

How you wash and care for garments with fusible interlining can greatly impact the risk of bubbling. Follow the washing instructions provided by the manufacturer to ensure you are using the correct temperature and agitation settings. Harsh detergents and bleach can damage the adhesive and fabric, leading to bubbling or delamination.

Application Technique

The way you apply the fusible interlining can make or break its effectiveness. Use proper application methods, including the appropriate heat and pressure levels during bonding. Incorrect application, such as uneven pressure distribution or inadequate heat, can result in areas where the interlining must adhere properly, leading to bubbling.

Be mindful of common mistakes, like overheating the adhesive or not allowing sufficient cooling time, as they can also contribute to bubbling issues in the long run. Attention to these factors can prevent bubbling and ensure your garments retain their professional appearance even after washing.

The Process of Bubbling

Detachment of Interlining From Fabric

The bubbling process typically starts with detaining the fusible interlining from the fabric. Over time and after several wash cycles, the bond between the interlining and the fabric may weaken due to various factors, such as low-quality adhesive or incompatible materials.

As a result, the once firmly bonded layers may begin to separate, creating a gap between the interlining and the fabric. This detachment can be exacerbated by improper washing practices, such as high-temperature water or harsh detergents, further weakening the adhesive bond.

Formation of Air Pockets and Bubbles

As the interlining detaches from the fabric, small air pockets form in the space between the layers. These trapped air pockets create the telltale sign of bubbling, causing the fabric to appear uneven or wrinkled.

With repeated washing and drying, these air pockets may expand and grow, leading to more noticeable bubbles on the garment’s surface. These bubbles not only affect the garment’s appearance but can also compromise its structural integrity and fit.

Impact on Garment Appearance and Performance

The bubbling caused by the detachment of the fusible interlining can significantly affect the overall appearance and performance of the garment. Visually, the bubbles create unsightly wrinkles and distortions on the fabric, giving the garment a shabby and unprofessional look.

Moreover, air pockets may affect the garment’s drape and fit, causing it to lose its intended shape and silhouette. Bubbling can be particularly problematic in tailored garments, such as blazers and dress shirts, where a smooth and structured appearance is essential.

Furthermore, the compromised bond between the interlining and the fabric can reduce durability. The garment may become more prone to wear and tear, resulting in a shorter lifespan. Additionally, bubbling can impact the garment’s comfort, as the uneven surface may cause irritation or discomfort to the wearer.

Preventive Measures

Selecting High-Quality Fusible Interlining

When preventing bubbling issues, the first step is to invest in high-quality fusible interlining. Take the time to understand the interlining specifications, such as its fiber content, weight, and adhesive properties.

Matching the right interlining to your specific fabric and garment type is essential for a successful bond that withstands washing. Look for reputable suppliers and trusted brands known for their commitment to quality. Reliable interlinings with well-tested adhesives are less likely to cause bubbling and will ensure your garments maintain their professional appearance over time.

Pre-testing Interlining and Fabric Compatibility

Before applying the fusible interlining to the entire garment, it’s crucial to conduct pre-tests to check for compatibility. Cut a small swatch of the fabric and apply a sample of the interlining using the recommended bonding process. Wash and dry the swatch following the fabric’s care instructions.

This wash test will help determine whether the interlining adheres properly to the fabric and whether bubbling issues arise. If problems occur during the test, consider trying a different interlining or adjusting the application technique before proceeding with the full garment.

Adhering to Washing Guidelines

Adhering to proper washing guidelines is one of the most important preventive measures against bubbling. Always follow the garment’s care instructions, which include recommended washing temperatures and cycles.

Using too hot water or subjecting the garment to harsh agitation can weaken the adhesive bond and cause bubbling. Also, choose detergents specifically formulated for delicate fabrics and avoid using bleach, which can damage the interlining and fabric.

Correct Application Techniques

Applying the fusible interlining during the bonding process greatly affects its long-term performance. Ensure you use the proper heat and pressure levels the interlining manufacturer recommends. Avoid overheating the adhesive, as it can lead to a weaker bond and potential bubbling issues later.

Additionally, different fabrics may require different application techniques, so adjust accordingly. For example, lightweight fabrics might need less heat and pressure, while heavier fabrics may require more.

Fixing Bubbling Issues

Possible Solutions for Minor Bubbling

If you notice minor bubbling on your garment after washing, there are some solutions you can try to salvage its appearance. First, attempt to gently press the affected areas with a steam iron. The heat and steam can help reactivate the adhesive and re-bond the interlining to the fabric.

\

Be sure to use a pressing cloth to protect the fabric’s surface from direct contact with the iron. This simple fix can often alleviate minor bubbling and restore the garment’s smoothness.

Removing and Reapplying Interlining

For cases where the bubbling is more severe or widespread, you may need to remove and reapply the fusible interlining. Carefully peel off the bubbling interlining from the fabric, taking caution not to damage the fabric in the process. Use a clean, damp cloth to gently remove any residual adhesive on the fabric.

Once the fabric is clean and dry, reapply a new piece of fusible interlining using the correct application techniques. Following the manufacturer’s guidelines for heat and pressure, bond the new interlining to the fabric. This method can be effective for garments with localized bubbling issues and ensures a strong and secure bond.

Salvaging Garments With Extensive Bubbling

Salvaging the item may require more advanced steps for garments with extensive bubbling that cannot be easily fixed with the above methods. Consider altering the garment’s design to incorporate the bubbling into the overall aesthetic.

For instance, you could add embellishments, appliqués, or extra layers to camouflage the affected areas. Alternatively, you may repurpose the garment into a different item, such as transforming a shirt into a stylish tote bag.

Conclusion

Understanding the causes of fusible interlining bubbling after washing is essential for garment manufacturers and consumers. Factors like interlining quality, fabric compatibility, washing practices, and application techniques all significantly prevent this frustrating issue.

By following preventive measures and adopting proper care, you can ensure your garments retain their smooth and structured appearance without the unsightly bubbling. With this knowledge, you can confidently select high-quality materials, implement best practices, and enjoy long-lasting, professionally finished garments that withstand the test of time and washing.