Introduction

Interlinings or interfacings are essential components of your fashion fabric garments that add body or structure. The interlinings can be fusible or sew-in. Some most common parts of the upper fabric that are known for using interlining are:

✔Cuffs

✔Waistbands

✔Button Packets

✔Collars

Using interlining is not enough. Instead, it would be best if you also focused on the durability and manufacturing of interlining. A low-quality interlining can result in damaging the critical parts of cloth and doesn’t add structure. A low-quality interlining can be unglued from your fabric and result in unevenness, puckering, rippling, and shifting from its place.

The best solution to prevent interlining problems is to check for defects and choose the right clothing parts before using them. You can do wonders to your clothes by using the correct type of interlining at the right place.

So, where and how can you strictly use the interlining? It is what you will learn in this article. Let’s dig into it.

What Is Interlining?

Interlining is an essential part of clothing that can fulfil your garments‘ functional and aesthetic aspects. However, people forget to make sure if the interlining can be used in a particular targeted area or not. Interlining is sewn between two layers of fabric to give your garments a more structured and firm look. You can use it in detailed areas of clothes.

The detailed area of clothes is that area that requires special effort and attention. These areas support the overall structure of your garments. For example, pocket flaps, front of the collar, neckline, waistband, and cuffs. You can use the interlining in two most common ways:

Sew-in interlining

Fused interlining

The first is stitched between two parts of the garments, while the second is fused to apply to your attire. In other words, the sewn interlining uses pressure and heat to bond powerfully with garments.

Not using the interlining correctly can result in problems such as bubbling, strikethrough, and strike back. Therefore, using the interlining in the right parts of your clothes can be quite a tedious and time-consuming task. You have to use different types of interlining according to other shirts. For example:

✔You have to maintain more stiffness in classic shirts.

✔It would help if you had more stretchability in the case of jersey shirts.

✔More heat sensitivity is required in the case of polyester and nylon shirts.

✔More body washability is required in uniform shirts, so you must use the interfacing accordingly.

How To Use Interlining In Collars And Cuffs?

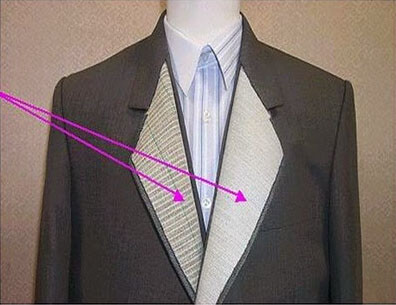

It is an essential part to know of this article. Knowing which parts use interlining isn’t the only thing. You also need to understand how to use the interlining in those parts. Interlinings are supposed to control different areas of garments by supporting and reinforcing them. These garment parts are the fronts of coats and jackets, facings, hems, and collars.

First, making the pattern of the parts where you will apply the interlining is essential. So you have to create patterns of cuffs and collars. You have to cut the way according to the design of the fabric, i.e. collar and cuffs. You have to cut two pieces of fabric pattern pieces for the construction details.

The next step is to take the part of nonwoven interlining or fusible interlinings you got for the collar or cuffs. You must place it carefully with proper care instructions on the targeted wrong side of fabric. If this is a fusible interlining, then you need to apply heat to it. You must stitch it using the sewing machine if it is a sewn interlining.

Then, you need to apply the other part of the interlining fabric over it as you cut down two layers of material according to the structure of the collar and cuffs. Now, you need to sew it to make the final product. It is how you will be using the interlining details. However, your choice of interlinings can make or break your garment fabric layers.

You may also face challenges such as shaping your collars can be the most frustrating part of collar construction. It is a common fact that flat fabrics hate to go around the curves. You can deal with this problem by trimming yours under collars. You must cut it 1/8th inch into seam allowance from the outside and the side edges.

It would help if you gently stretch the collar and undercollar when you pin the collar and undercollar together. It will help to fit it with perfection.

Turning the collar points can also be a problem, but you can do it easily using a thread loop.

Make sure that you edgestitch your collar if you are looking for a professional finish to it.

Get yourself a tailor’s ham if you properly finish it off. A curved surface can finish it off properly by pressing it against the surface.

How To Use Interlining According To Different Shirts?

As mentioned earlier, you need to use interfacing in different ways to maintain the structure of other shirts. So let’s start:

Using Interfacing In Classic Shirts

The most significant upcoming trend these days is to get yourself a classic shirt with a comfortable and stiff interlining collar. It is essential to use interfacing made with 100% cotton fabrics to maintain the stability and stiffness of your collar, i. The cotton interfacing’s stiffness doesn’t let it distorted easily. Whether you wear or clean it, the interfacing will have higher stiffness.

The 100% cotton lawn interfacing can have maximum control on shape retention and shrinkage of the garment components. You should use lightweight cotton fusible interfacing to achieve a perfect aesthetic requirement.

Using Interlinings In Jersey Shirts

Due to his hectic routine, an office goer always demands a comfortable and stretchable collar. Therefore, when garment manufacturers or suppliers produce their garments, they seek more stretchability in shirts. It is also mentioned that jersey shirts should be manufactured in such a way that there is the ease of movement.

Plan stretch fabrics, knits, and jersey fabrics with cotton spandex are becoming a new trend in the shirts manufacturing industry. The interfacing used in the jersey shirts should match the material’s properties. Regular cotton interfacing may not work perfectly for jersey shirts. Bi-elastic interfacing may help you serve the purpose of supporting the outer fabric.

Using Interlinings In Nylon Or Polyester Shirts

There is a large variety of fabrics available in the market with different weights and characteristics. It will help if you consider these things before performing any treatment on your material. Polyester and nylon fabrics are known for their super soft properties. At the same time, they are also known for their higher heat sensitivity.

The higher heat sensitivity can also make the interfacing fusing process difficult. The standard classic fusible interfacing may not yield desired results due to higher thermal shrinkage. You can deal with the higher heat sensitivity of this fabric by choosing the suitable adhesive with your polyester or nylon fabric.

It would help if you chose lightweight interfacing for a lightweight fabric. It will manage the weight differences between the main fabric and the interfacing.

Using Interlinings In Uniform Shirts

As you know that uniform shirts are used daily, and you require more washability in these shirts. At the same time, you must choose the interlinings that should not get damaged when these shirts are washed repeatedly. Most sellers use bad interlinings in uniform shirts that give rise to interlining problems such as bubbling.

It will help if you try to use a high-quality separate layer of interlining so that it is not affected by more washes.

Reasons For Adding Interlining To Your Shirts

You have come across methods and a selection of the right interlinings in this blog. However, it is also essential to know whether you need interlinings or not. Some common reasons are given here to learn why you need to add interlinings to your shirts. These reasons are given below:

- An additional firm layer helps to add body to your garments. It is possible only through the use of interlinings.

- Some fabrics are prone to creasing due to their construction from natural materials. You can prevent the creasing by using high-quality interlinings.

- Interlinings also tend to avoid seating in clothes such as a slim-fitting skirt or fitted sleeve of a jacked. In this case, a 100% silk organza interlining is highly suitable.

- Interlinings also help to add drape and density and create a skeleton to your garments.

- Interlinings are the best solutions to prevent ridges and change the characteristics of your fabrics.

Conclusion

Interlinings are the best things to be used in your garments for support, comfort, and much more. However, choosing high-quality interlining also matters when you want your garment to last longer. So, are you ready to invest in high-quality interlinings? Reach Us now.