Introduction

Have you ever wondered about the glue that holds fabrics together, especially inside clothes or furniture? Well, that glue is essential for keeping things in place. Some folks think that if the glue is bright, it makes everything better. But is that true? We’re here to figure out if the glue’s brightness on the lining cloth makes a difference.

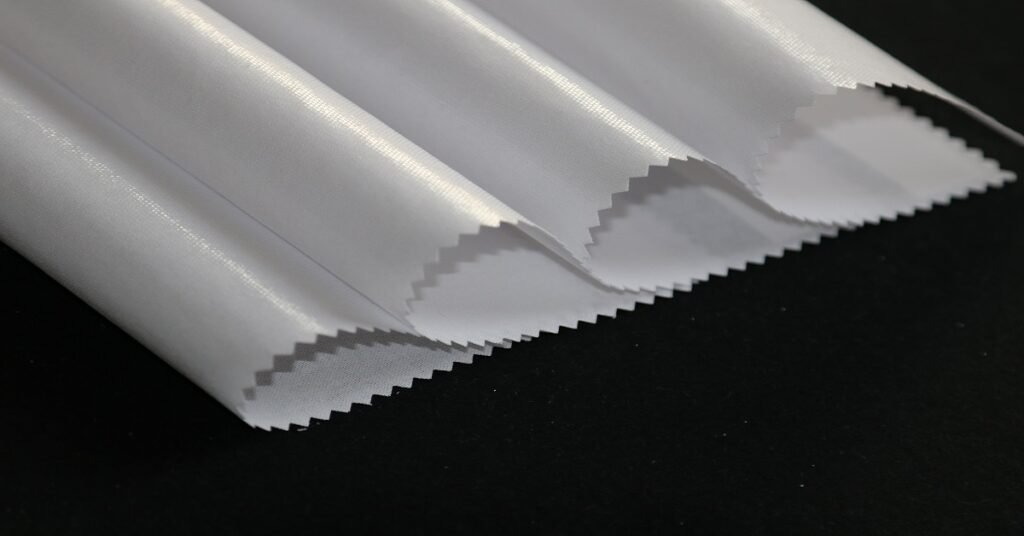

Lining cloth is the material inside clothes or furniture; glue keeps it all together. People believe the glue looks good and works better if it is super bright. In this blog, we will learn about the basics of lining cloth and what the glue does.

We will also learn whether having bright glue is the secret to better quality. So, let’s find out if the brightness of the glue is as important as it seems in our everyday fabrics!

What Are the Different Types of Lining Cloth and Their Applications?

Lining cloth is like a behind-the-scenes hero in our clothes and furniture. Let’s break down the basics of what it is and where we see it.

Types of Lining Cloth

Natural Fabrics

Some lining cloths are made from cotton, silk, and wool. Cotton feels nice on your skin and is used in everyday clothes. Silk is super fancy and found in high-end clothing. Wool keeps you warm, perfect for chilly weather.

Synthetic Fabrics

People make others and include fabrics like polyester, nylon, and acetate. Polyester is tough and doesn’t wrinkle, often seen in jackets. Nylon is light and used in sporty clothes. Acetate feels silky and shows up in dressy outfits.

Applications of Lining Cloth

Fashion Industry

In fashion, lining cloth is like a comfy and hidden friend in clothes. Cotton linings make dresses smoother, and polyester linings give jackets a good shape. The kind of lining used depends on how the clothes look and feel.

Upholstery

Lining cloth is also a big deal in furniture. For cushions and sofas, they might use soft cotton or wool. If they want furniture to resist stains and last long, they’d go for synthetic fabrics like polyester.

Industrial Uses

Even in big machines and factories, lining cloth has a job. It helps reduce friction and make things work better. They might pick tough synthetic fabrics like nylon to handle the demands of machines.

What Functions Does Glue Serve in the Context of Lining Cloth?

The function of Glue in Lining Cloth

Think of glue as the superhero that keeps lining cloth together. Its main job is to make sure different layers of fabric stick together so your clothes or furniture stay intact and don’t fall apart. The glue is like the invisible force holding everything in place, ensuring the fabric stays strong and in good shape.

Common Types of Glues Used

Water-Based Glues

These glues are like the friendly helpers of lining cloth. They’re easy to use and don’t have any nasty fumes. Water-based glues create a strong bond between fabrics without causing any harm.

Solvent-Based Glues

Solvent-based glues use some chemicals to do their job. They’re tough and long-lasting, but you must be careful because they might produce strong smells. People use them when they want durable glue for the fabric.

Hot-Melt Glues

Hot-melt glues are like magic – they become liquid when heated and solid again as they cool. They work fast and create a strong bond. However, they might act differently depending on the temperature.

Impact of Glue on Lining Cloth Durability

Choosing the right glue is like picking the right tool for the job. The kind of glue used in lining cloth decides how tough it will be. If you choose a good glue, your fabric will stay strong and last long. But if you pick the wrong glue, your clothes or furniture might peel or fall sooner than you’d like.

Why Is There a Preference for Brighter Glues in the Industry?

Reasons for Using Bright Glue

Aesthetics

Bright glues are like the artists of the fabric world. They make the glue lines visible and add a touch of style to the final product. Using bright glue is like giving your fabric a subtle, decorative touch that enhances its overall look. This aesthetic appeal is why many people in the industry prefer brighter glues.

Visibility During Application

Think of bright glue as a guiding light during the process. Applying glue to fabric, especially in industries like garment manufacturing, helps to see where the glue is going. Bright glue provides a clear view, making it easier for workers to apply it precisely where needed. This visibility ensures that the glue does its job effectively.

Potential Drawbacks of Bright Glue

Discoloration Over Time

Bright glues, while visually appealing initially, can face a challenge over time. They might lose their brightness and start to change color, leading to discoloration. This could affect the overall appearance of the fabric, causing it to look different than intended.

Impact on the Fabric’s Appearance

Sometimes, the brightness of the glue can have unintended consequences. It might clash with the fabric’s color or design, altering the intended appearance. When choosing bright glue, this impact on the fabric’s look is something to consider.

How Does the Type of Fabric Influence the Choice of Glue for Lining Cloth?

Fabric Type

Think of the fabric as the leader in choosing the right glue for lining cloth. Different fabrics need different kinds of glue. Soft fabrics like cotton prefer gentle glue, while tougher ones like leather need stronger glue to keep everything together.

Intended Use of Lining Cloth

Consider what the lining cloth will be doing. Is it part of a cozy shirt or a tough jacket? The job it has to do influences the glue choice. Everyday wear needs flexible and comfy glue, but heavy-duty work uniforms need tougher glue to handle rough situations.

Manufacturing Process

How the lining cloth is made matters, too. The way the fabric comes together can affect the type of glue used. Some glues work better with certain fabric-making methods, ensuring the lining stays put during the making process.

Environmental Considerations

Let’s not forget about our planet. Some glues are more eco-friendly than others. Manufacturers might choose glues that are kinder to the environment, especially as people become more aware of the impact of their choices. Going for a glue that sticks things together without causing harm to the planet is a good move.

How Can the Optimal Level of Brightness in Glue Be Determined for a Balanced Aesthetic and Practical Outcome?

Finding the Optimal Level of Brightness

Selecting the right brightness for glue is like picking the perfect outfit. It should enhance the fabric’s look without being too flashy. The goal is to ensure the glue matches the color and design, adding a nice touch without being too overwhelming. The ideal brightness is all about making the fabric look good.

Considering Long-Term Effects

Imagine brightness as a long-term commitment. What looks good today should still look good tomorrow. Bright glues might lose their shine over time and change color. So, when choosing brightness, it’s essential to think about how it will hold up in the future. It’s about balancing making a good first impression and lasting over time.

Balancing Aesthetics With Functionality

It’s not just about how good the glue looks; it’s also about how well it works. Bright glues should make the fabric look better without causing any unexpected problems. Striking this balance ensures that the fabric looks good at the start, stays that way, and does its job well in the long run.

What Recent Developments Have Been Made in Glue Manufacturing Technology for Lining Cloth?

Recent Developments in Glue Manufacturing

Picture Glue getting a cool upgrade, like your phone getting new features. That’s what’s happening in glue making. They’re making stronger glues that last longer and are easier to use. It’s like giving lining cloth a boost, improving it.

Environmentally Friendly Glues

Nowadays, it’s not just about how well it works; it’s also about being kind to the planet. Eco-friendly glues are like the heroes of the glue world. They get the job done without hurting the environment. People like these glues because they’re better for the Earth.

Impact of Technology on Lining Cloth Production

Technology is making things different in how they make lining cloth. New tools and ways of doing things make the process smoother and better. From putting on glue just right to making the cloth stronger, technology is helping make really good lining cloth. It’s like going from a regular car to a super fancy, high-tech one for fabric.

What Perspectives Do Industry Professionals Have on the Relationship Between Glue and Lining Cloth?

Insights From Industry Professionals

Let’s hear from the pros—the people who know their stuff about lining cloth. Industry professionals working closely with fabrics have a lot to share. They discuss which glues work best, how to improve them, and the secrets to creating awesome lining cloth.

Perspectives From Textile Engineers

Fabric engineers, the smart minds behind fabric inventions, also have something to say about glue. They study fabrics and glues, determining the best strength, comfort, and durability combos. Their ideas go deep into the technical side, making sure the glue not only sticks things together but does it in the smartest way possible.

Consumer Preferences and Feedback

And, of course, let’s not forget about us—the people who wear and use the lining cloth daily! What we like and how the lining feels against our skin matters. Our opinions shape the glue choices. If we love how a particular lining cloth feels and looks, it’s probably because the professionals listened to what we wanted.

Lining Cloth: Conclusion

The brightness of the glue in the lining cloth is like choosing the right seasoning for your favorite dish—it adds a touch of flavor. While a bit of brightness can enhance the appearance, finding the right balance is essential. Too much brightness might fade, affecting the look of your clothes or furniture.

Experts, like fabric engineers and industry professionals, play a vital role in determining the best fabric glue. And guess what? Your opinion matters, too! So, just like finding the perfect seasoning, it’s about finding the right brightness that makes your lining cloth look good and stay good for a long time.

Contact us today to purchase high-quality lining cloth for your garment manufacturing business.