Introduction

If you are a garments manufacturer, you must know the complicated process of suit production. In simple words, suits are the most complex clothes you ever produce. It would be best if you considered different aspects when starting the construction of a suit. You think of many design choices, from the cuff break to the lapel roll and the internal layer.

But when you are a customer looking to buy a suit for your office or an event, you may also think about it. Since you want to put a good impression on your colleagues, friends, or relatives, you will try to get the right suit. At that moment, it is also essential that you know the case production process.

Some people prefer to get their suits stitched by themselves rather than purchasing a ready-made case. Therefore, it is essential to know the role of interlining in suit production. So this article is all about the selection and basics of interlining in suit production. Let’s dig into it.

What Is Interlining?

If you are a regular suit buyer, the term interlining might not be new to you. But if you are a beginner trying to gain some knowledge, you must know it is an essential aspect of your clothes. In simple words, interlining supports and gives shape to your clothes. And it is a common fact that having a body and support is ESSENTIAL in suit production.

Interlining is a fabric between your suit’s external and internal layers. Your claim can hold shape only due to the presence of interlining. It is more like a skeleton under your case. However, it is also essential to know that interlining comes in various types and qualities. And you must choose the right quality to ensure a quality suit construction.

The interlining you choose depends on the suit construction. At the same time, the suit jacket construction techniques also depend on your affordable budget.

Why Do you Need a Suit Interlining?

First, you must be very clear about why you need an interlining in suit production. When you are dealing with a simple fabric, it is primarily two-dimensional. A two-dimensional fabric can be either flat or woven. On the other hand, the suit is not the same as other materials or fabrics. It has more like a three-dimensional shape.

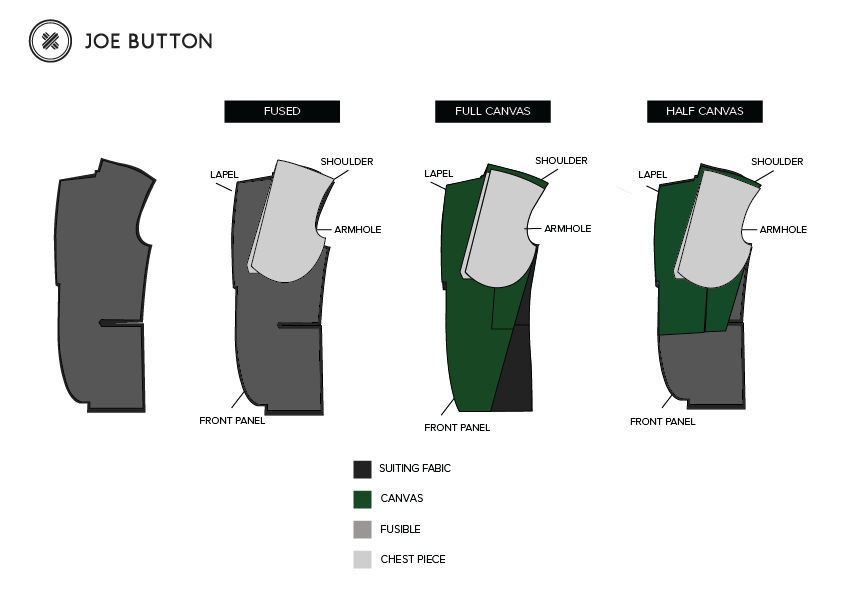

A suit is flattering to your body’s shape. Therefore, you need to choose interlining to keep your suit in a three-dimensional shape. When you look for suit interlining, you come across various options and types. The most popular ones have glued suits, fused suits, half canvas, and full canvas construction options. Let’s explore all these available options.

Suit Construction Options

Fused Interlining: Low Quality & Prices

It is a thin layer of fabric that you use in between the external and internal layers of the main fabric. Since it is easy to produce, you find suits will fuse interlining less expensive. 95% of suit production is merged suit production, but some downsides exist. The combined case is stiff, less breathable, and requires excessive dry cleaning, degrading the suit’s quality finish.

Canvassed Interlining: High Quality & High Prices

If you are willing to buy a high-quality suit and spend some extra costs, you should buy a canvas suit. Canvassed suit interlining is mostly produced from horse hair or linen. Other variations may also exist in the canvassed suit. The best part about it is that it is highly breathable. A canvas suit moves and shifts with your body.

Full Canvas Construction

You must know that a canvas suit is more time-consuming and expensive than compared to fused suit. You can see a reflection of the quality in the high price. If you want a bespoke suit from the tailor, make sure it is a canvas suit. There is no point in getting your bespoke suit as a fused suit. It is more like wasting your money.

Half Canvas Interlining

If you can’t afford the price for a complete canvas construction, you may also go for a full canvas suit. This type of suit combines canvassed interlining and fused suit interlining. The canvas interlining exists in the lapel, chest piece, and down to the pocket in a half-canvas construction. The lower half part of the suit jacket construction is fused interlining.

How To Tell If Your Suit Is Fused Or Full Canvas?

What if you bought a suit from a shop and didn’t know its type? This situation can be a little complicated since you don’t want to spend without verifying the type and quality of the suit. In such a case, you can tell the kind of suit between fused or entire canvas through the help of a pinch test.

You need to use the two fingers to separate and pinch the outer and inner layers on the chest piece. If you find a third layer between the internal and external layers of the suit, it means that your case is composed of canvas interlining. On the other hand, if you don’t feel the third layer, you must be sure that the suit is manufactured from fused interlining.

Which Suit Interlining Option Should You Choose?

No matter the situation, you should always go for canvas construction. Even if you choose a half-canvas building, it is much better than selecting a fused interlining in your suit. A canvassed suit, whether half or whole, can help to achieve a suit jacket support with perfection.

An interesting fact is that the more you use a canvassed suit, the more it will fit your body. Canvas construction can be your best partner if you want a proper fit. Canvas suits are not the cheapest options, but they last longer.

On the other hand, the fused suit is not such a good option for you. Even if you buy a half-canvas suit jacket, your body and closet will thank you.

Selection Of fusible Interlining In Suit Production

First, it is essential to be clear about the type of base fabric. Once you know the base fabric, choosing the right type of interlining for your suit becomes quite easy. Now, when you talk about base fabric, you may come across options such as non-woven fabric, knitted fabric, and woven fabric.

Important Points To Know

After choosing your base fabric, you must pay attention to the following essential points:

- You should feel the thickness and stiffness. When you bond the interlining, you will feel the stiffness in the hot melt bonding part. When choosing the appropriate feel, you need to ensure the stiffness degree in each part of your suit.

- When choosing a non-woven fabric, we need to check if its heating bonding is unsuitable for the rugged feel.

- We must check the dimensional stability. If we choose a fusible interlining, we must ensure that it is stable enough after being dry-cleaned or washed.

- There should be soft interlining in your suit’s upper and lower directions. It must be quiet in the warp and firm in the weft or transverse direction. Most knitted, woven, or non-woven substrates carry different warp and weft direction characteristics. So make sure they maintain consistency with your fabric.

- You must follow the capabilities and characteristics of your fabric. The warp direction of the bonded interlining mostly matches the warp characteristics of your material. Make sure that your interlining is thinner and lighter than your fabric. Your material will drive the interlining, not the one that goes with your material.

- According to the washing requirements of your suit interlining, you should select the suitable adhesive or colloid. In general cases, your claims are chemical resistant and washable. So, it would be best if you chose a high-quality PA colloid.

Is There Any Role Of Price In Choosing Interlining For Suits?

You must know that you can purchase suits at varying prices. Some cases are as low as $50. At the same time, you can also find suits that cost even more than a thousand dollars. Different factors affect the prices of cases. And one of those factors is the interlining. The higher the quality of interlining, the higher will cost.

Note that canvas interlining is expensive compared to fused interlining.

Conclusion

When selecting an interlining for suit production, you must ensure all the points given above. Choosing a fused interlining is a good option but choosing the canvas construction is the best thing you can do. Contact Us now if you want to deal with a high-quality interlining manufacturer from China.