Introduction

Interlining is a layer of fabric used inside shirts. It strengthens and shapes areas like collars, cuffs, and plackets. The right interlining makes a shirt look neat and last longer

There are many types of interlining. They differ in material, thickness, and how they attach to the shirt. Using poor-quality interlining can cause issues. The shirt may lose shape, shrink, or look uneven after washing.

Choosing interlining depends on the type of shirt and fabric. Casual shirts need soft interlining for comfort. Formal shirts require stiffer ones for a clean, structured look. Understanding how to select high-quality interlining is important. It improves the shirt’s comfort, durability, and style. This guide will help you make the right choice for your shirts.

What Is Shirt Interlining and Why Is It Important?

Shirt interlining is a hidden fabric layer placed between the outer fabric. It adds strength, structure, and stability. Interlining is mostly used in collars, cuffs, and plackets to give them a firm, clean look. Without interlining, these parts can appear limp or lose shape over time.

Interlining plays a key role in enhancing the shirt’s quality. It helps maintain the shirt’s form and ensures durability. A well-chosen interlining improves comfort and makes the shirt look polished and professional.

There are two types of interlining: fusible and sew-in. Fusible interlining is bonded to the fabric using heat. It is commonly used because it is faster and easier to apply. Sew-in interlining is stitched into the fabric and offers a more traditional method.

Interlining also varies in weight: light, medium, and heavy. Light-weight interlining is suitable for soft, casual shirts. Medium-weight is used for semi-formal shirts, while heavy-weight is best for stiff, formal designs.

What Types of Interlining Are Available for Shirts?

Interlining for shirts comes in different types based on attachment, material, and weight. Each type serves a specific purpose and is chosen according to the shirt’s style and fabric.

Based on Attachment

- Fusible Interlining: This type sticks to the fabric using heat and adhesive. It is widely used because it is easy to apply and saves time. However, poor-quality fusible interlining may bubble if not applied properly.

- Sew-in Interlining: This type is stitched into the fabric. It is often used in high-end or custom shirts. Although it takes more time to apply, it gives a softer and more natural look.

Based on Material

- Cotton Interlining: Soft, breathable, and used for premium shirts.

- Polyester Interlining: More affordable, durable, and wrinkle-resistant.

- Blended Interlining: Combines the benefits of cotton and synthetic materials.

Based on Weight

- Light-weight: Best for soft, casual shirts.

- Medium-weight: Suitable for semi-formal shirts.

- Heavy-weight: Ideal for formal shirts that need a crisp and stiff look.

Where Is Interlining Used in a Shirt?

Interlining is used in key parts of the shirt to add shape and structure. Each area requires a specific type of interlining to maintain its form and improve durability.

Collars

The collar is the most important part of a shirt for interlining. It needs to stay firm and hold its shape throughout the day. Soft collars require light interlining for comfort, while formal collars need medium or heavy interlining for a crisp look.

Cuffs

Cuffs also need interlining for strength and shape. Barrel cuffs and French cuffs benefit from medium or heavy interlining. This prevents them from wrinkling or folding over time.

Plackets

The placket is the front opening where buttons are placed. Interlining in this area keeps the placket firm and prevents it from sagging. Medium-weight interlining is usually used to provide the right balance of structure and flexibility.

Pocket Flaps

In shirts with pockets, interlining is often added to pocket flaps to keep them neat and prevent curling.

Other Areas

Interlining can also be used in shoulder areas or buttonholes for extra reinforcement.

How to Choose the Right Shirt Interlining?

Choosing the right interlining is critical for shirt quality. The wrong interlining can cause issues like bubbling, shrinking, or stiffness. Follow these steps to make the right choice.

Match with Fabric Type

The interlining should be compatible with the shirt fabric. For light-weight fabrics like cotton or linen, use soft or light-weight interlining. Heavier fabrics need medium or heavy-weight interlining.

Decide Based on Shirt Style

The purpose of the shirt affects interlining choice. Casual shirts need soft interlining for comfort. Formal shirts require crisp, structured interlining to maintain a professional look.

Check Durability and Washability

Choose interlining that can withstand frequent washing and ironing. Poor-quality interlining may shrink or lose shape after washing.

Focus on Comfort

The interlining should not affect the shirt’s breathability. Choose breathable materials, especially for summer shirts.

Balance Cost and Quality

High-quality interlining may cost more but ensures better results. Avoid sacrificing quality for a lower price.

How to Identify High-Quality Shirt Interlining?

High-quality interlining is crucial for making durable and well-structured shirts. It enhances the appearance of collars, cuffs, and plackets while improving comfort and longevity. Identifying high-quality interlining requires a few simple tests and observations.

Touch and Feel Test

High-quality interlining feels soft yet firm. It should have a smooth texture without roughness or stiffness. Run your fingers across the surface to check for an even thickness. Avoid interlining that feels too stiff or rough, as it may make the shirt uncomfortable to wear.

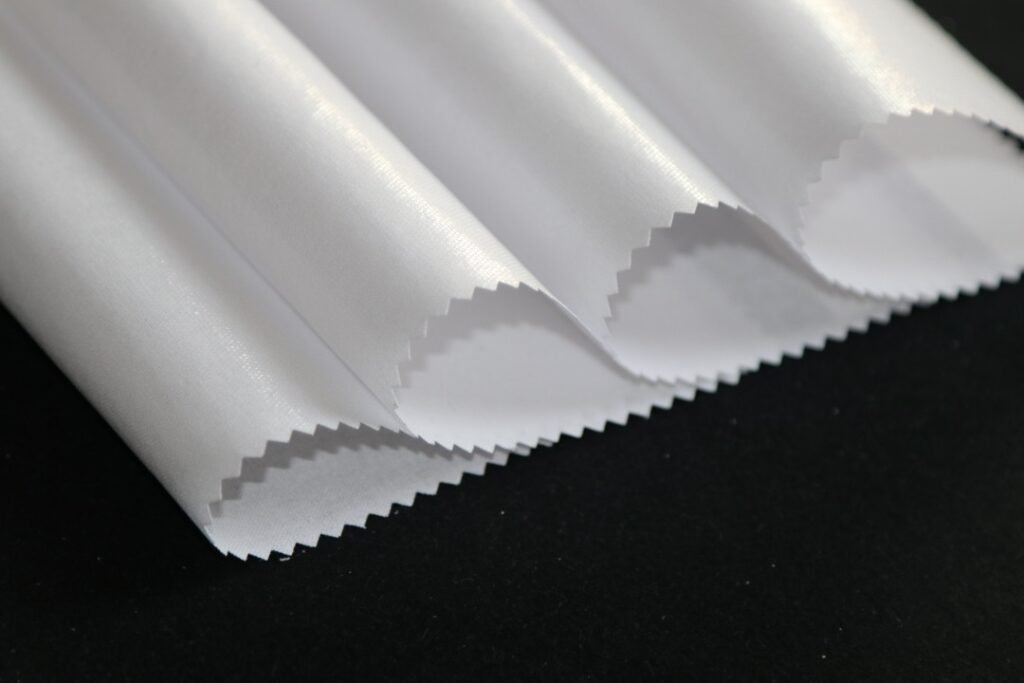

Visual Inspection For High-Quality Shirt Interlining

Examine the interlining for any visible defects. For fusible interlining, ensure the adhesive layer is consistent and smooth. Check for bubbles, uneven areas, or spots that may cause issues after application. Uniform thickness is a good sign of quality.

Wash Test

Wash a sample of the interlining to check its performance. High-quality interlining should maintain its shape and texture after washing. It should not shrink, bubble, or wrinkle. Poor-quality interlining often loses its stability and affects the shirt’s durability.

Stretch and Durability Check

Lightly stretch the interlining to test its strength. High-quality interlining is flexible but strong enough to resist tearing. Weak interlining may affect the shirt’s longevity, especially in areas like collars and cuffs that undergo frequent movement and wear.

Work With Trusted Suppliers

Reputable interlining manufacturers follow strict quality standards. Always request samples before purchasing in bulk. Certified and tested interlining is more reliable and consistent.

What Are Common Mistakes to Avoid When Choosing Interlining?

Selecting the wrong interlining can ruin the overall quality of a shirt. It may affect the fit, structure, and durability of important areas like collars, cuffs, and plackets. To achieve the best results, avoid these common mistakes when choosing interlining.

Ignoring Fabric Compatibility

The interlining must match the weight and texture of the shirt fabric. For light fabrics like cotton or linen, use soft or light-weight interlining. Heavy-weight interlining on such fabrics makes the shirt stiff and uncomfortable. For thicker fabrics, medium or heavy interlining is more suitable for maintaining structure and form.

Choosing Low-Quality Fusible Interlining

Poor-quality fusible interlining can cause bubbling, peeling, or distortion after washing. These defects make the shirt look cheap and affect its durability. Always test fusible interlining before large-scale production to ensure it bonds well and remains stable after washing.

Using the Wrong Weight

The weight of the interlining affects the final look and feel of the shirt. Heavy interlining is too stiff for casual shirts, while light-weight interlining on formal shirts won’t provide the necessary structure. Carefully choose the appropriate weight based on the shirt’s purpose and fabric.

Ignoring Washability

Some interlinings may shrink or lose their shape after washing. This can distort the shirt’s appearance and reduce its lifespan. Use washable interlining that holds up well under frequent washing and ironing.

Sacrificing Quality for Cost

Low-cost interlining may save money in the short term but can lead to long-term issues. Cheap interlining often results in lower durability and customer dissatisfaction. Investing in high-quality interlining ensures a better-looking and longer-lasting shirt.

Conclusion

Choosing the right shirt interlining is very important. It makes the shirt look good, feel comfortable, and last longer. Always match the interlining with the fabric and the shirt’s purpose. Use light, medium, or heavy interlining, depending on the style you want.

Avoid common mistakes like using poor-quality interlining or the wrong weight. Test the interlining by touching, washing, and stretching it to check its quality.

Good interlining helps you make better shirts that hold their shape and last after many washes. It improves the shirt’s overall quality and keeps customers happy. Following these tips will help you choose the best interlining for every type of shirt.

FAQs

How to Choose a Good Quality Shirt?

Check fabric quality, stitching, fit, interlining, comfort, durability, and washability before buying.

What Is the Purpose of Interlining?

Interlining adds structure, support, durability, and shape to shirt collars, cuffs, and plackets.

What Are the Characteristics of Interlining Fabric?

Interlining fabric is durable, soft, breathable, shrink-resistant, and available in different weights and types.