Introduction

Are you looking to create the perfect suit that exudes elegance and style? The key lies in choosing the right fusible interlining. Understanding the significance of this crucial component is essential in achieving a well-tailored masterpiece. This comprehensive guide will walk you through selecting the ideal fusible interlining for your suits.

From understanding the different types of interlining materials to matching them with suit fabric, we’ve got you covered. Unravel the mysteries behind interlining weights, explore their impact on suit aesthetics and performance, and gain valuable insights into application and sewing techniques. Get ready to craft impeccable suits with the perfect fusible interlining!

Understanding Fusible Interlining

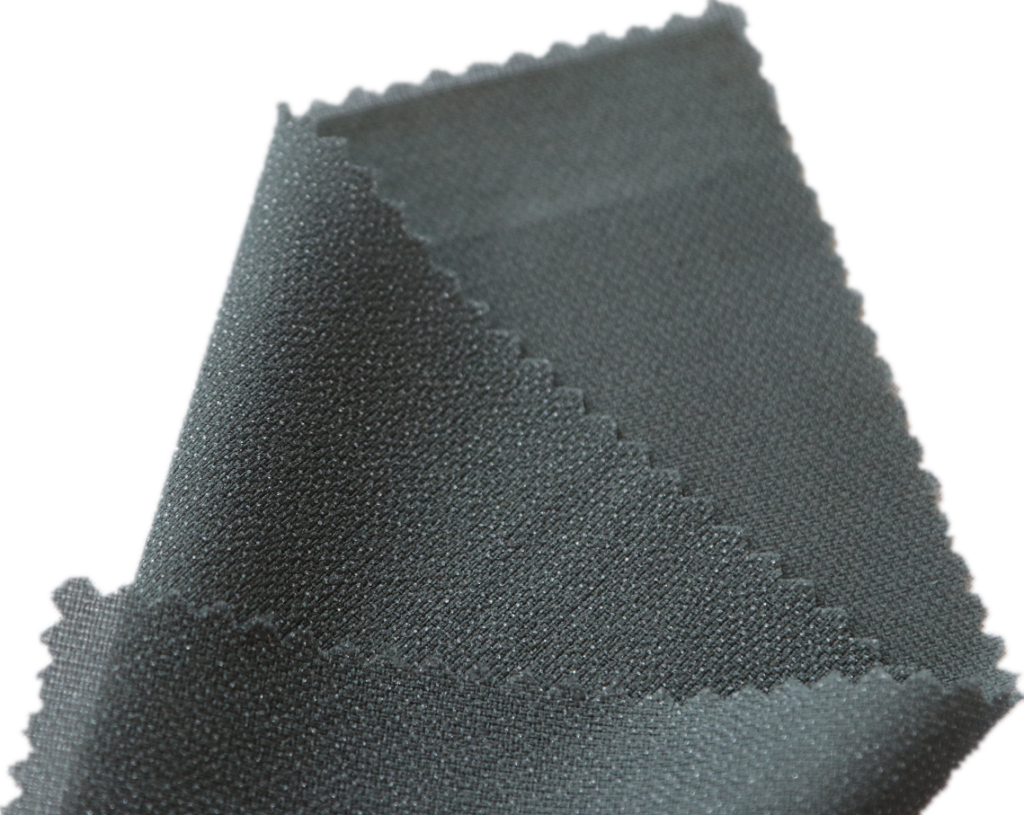

In your quest for the ideal suit, understanding fusible interlining is paramount. Fusible interlining refers to a fabric with adhesive properties that, when activated by heat, adheres to the suit fabric, adding structure and support. This vital component ensures your suit maintains its shape and enhances its overall appearance.

Regarding suit construction, fusible interlining is crucial in stabilizing and reinforcing various parts, such as lapels, collars, and facings. It aids in achieving clean lines and sharp edges, contributing to a polished and professional look.

Various types of fusible interlining materials are available, each with unique characteristics and applications. Non-woven, woven, and knit interlinings offer different levels of stiffness and drape, making it essential to choose the right one to complement your suit fabric and design.

Determining Suit Fabric Compatibility For Fusible Interlining

When determining suit fabric compatibility with fusible interlining, consider matching their weights. Light suit fabrics pair well with lighter interlinings, while heavier fabrics demand more substantial interlinings to maintain balance and drape.

Suit fabric composition also plays a vital role. Natural fibers like wool or cotton may require different interlining materials than synthetic fibers such as polyester. Understanding these differences ensures a harmonious blend between the suit fabric and interlining.

Don’t forget to address suit fabric stretch and drape as well. Ensuring the interlining accommodates the fabric’s stretch and complements its drape will result in a comfortable and well-fitted suit.

Evaluating Suit Construction Needs

Evaluating your suit construction needs is essential to create a suit that truly reflects your style. Start by identifying the suit style and design you desire. The interlining choice will influence the final look, whether a classic single-breasted suit or a more contemporary double-breasted one.

Consider the suit layers, including lining, canvas, and other components. Each layer may require a different type or weight of interlining for optimal performance and structure.

Furthermore, assess your tailoring goals and performance requirements. Choosing a robust and long-lasting interlining is crucial if you seek a suit with exceptional durability. Tailor your interlining selection to your specific preferences and aspirations for the perfect suit.

Exploring Interlining Weights and Thickness

As you delve into the world of interlining, understanding the various weights and thicknesses is vital. Light interlining offers flexibility and a softer feel, ideal for lightweight and casual suits.

Medium interlining strikes a balance, providing support and comfort, making it a popular choice for versatile suits. On the other hand, heavy interlining delivers structure and rigidity, perfect for formal and structured suits.

Different suit components require varying interlining weights to achieve the desired outcome. Collars and lapels may benefit from a stiffer interlining, while linings and pocketing might work better with a lighter one.

Choosing the right interlining weight significantly impacts your suit’s aesthetics and comfort. It can influence the drape, shape, and overall feel, ensuring your suit complements your style and comfort preferences.

Different Fusible Interlining Materials

As you explore the world of fusible interlining, you’ll encounter various materials designed to cater to different suit requirements. Non-woven fusible interlining is popular for its stability and ease of use, making it suitable for a wide range of suits.

Woven fusible interlining offers excellent breathability and durability, ideal for lightweight and breathable suits. Knit fusible interlining, with its stretch properties, is perfect for more fitted and comfortable suits.

For specific suit parts, specialty interlinings come into play. Collar and lapel interlinings provide stiffness and shape while pocketing interlinings maintain the pocket’s structure.

Choosing the right material ensures your suit achieves the desired appearance and performance effortlessly.

Testing Fusible Interlining Quality

When it comes to the fusible interlining, testing its quality is crucial for a successful suit. Proper adhesion and bonding are essential to ensure the interlining stays in place during wear and laundering. Perform a simple test to check if the interlining adheres evenly to the fabric without any bubbles or wrinkles.

Evaluate the durability and longevity of the interlining by subjecting it to simulated wear and tear. This will give you insights into how well it holds up over time.

Also, verify the interlining’s shrinkage and heat tolerance to ensure it remains stable and unaffected during the pressing process. Rigorous testing guarantees reliable and high-quality interlining for your suit.

Choosing the Right Interlining for Different Suit Parts

Choosing the right interlining for different suit parts is crucial to achieving a well-tailored masterpiece. Opt for medium to heavy-weight interlining for lapels, collars, and facings to provide the desired structure and crispness.

Front panels and pocket areas benefit from light to medium-weight interlining to maintain a smooth appearance without adding unnecessary bulk. Sleeve heads and cuffs require a balance of stiffness and flexibility, making a medium-weight interlining the ideal choice.

When it comes to trouser waistbands and pocketing, a sturdy and durable interlining ensures the waistband retains its shape and pockets remain sturdy during use. Tailoring each part with the right interlining enhances your suit’s overall fit and finish.

Considering Environmental and Ethical Factors

Considering environmental and ethical factors in your interlining selection is essential in today’s world. Look for sustainable and eco-friendly interlining options from renewable resources or recycled materials. These choices contribute to reducing the fashion industry’s environmental impact.

Ethical sourcing and manufacturing practices are equally important. Opt for supplier interlinings committed to fair labor practices and responsible production methods. Supporting ethical practices ensures that the people involved in the interlining supply chain are treated fairly and ethically.

By making conscious choices, you can create a great suit that aligns with your values and contributes to a more sustainable and responsible fashion industry.

Availability and Budget Considerations

When choosing fusible interlining for your suits, availability and budget considerations play a significant role. You can find interlinings from local fabric stores or online suppliers. Local suppliers offer immediate access and the ability to inspect the material before purchase, while online suppliers often provide a broader range of options.

Evaluating interlining costs is crucial to staying within your budget. Different types and brands of interlining come at varying price points, so comparing prices and quality is essential.

Balancing quality and budget constraints is essential. While it’s tempting to opt for cheaper options, compromising on quality may affect the outcome of your suits. Strive to find the right balance between cost and value to ensure a well-crafted and cost-effective result.

Tips for Application and Sewing

Mastering proper cutting and placement techniques is crucial to successfully apply fusible interlining in your suits. Cut the interlining accurately to match the pattern pieces, and place it precisely on the fabric to achieve consistent results throughout the suit.

When sewing interlined suit components, use the right needles and thread suitable for the specific interlining material. Adjust your sewing machine settings to accommodate the interlining’s thickness without compromising the fabric.

Pay attention to pressing techniques, using a pressing cloth to protect the fabric and interlining from heat damage. These tips will help you seamlessly integrate the interlining into your suit construction, resulting in a professionally tailored garment.

Troubleshooting and Common Mistakes

Encountering issues with fusible interlining during suit construction is common, but knowing how to troubleshoot can save your project. Bubbling or wrinkling can occur if the interlining doesn’t adhere properly. To fix this, use a pressing cloth and apply heat and pressure evenly. Ensure your iron is set at the correct fabric temperature and interlining temperature.

Interlining mismatch issues may arise when you use the wrong type or weight of interlining for a particular suit part. To avoid this, carefully select the appropriate interlining based on the fabric and suit component. Test a small sample before applying the interlining to the suit to ensure compatibility. By addressing these common mistakes, you’ll achieve a flawlessly interlined suit.

Conclusion

Congratulations! You have now mastered choosing the perfect fusible interlining for your suits. Understanding the various interlining materials, weights, and their compatibility with different suit parts is essential in achieving a well-tailored masterpiece. Consider your suit fabric’s composition, style, and tailoring goals while balancing quality and budget constraints.

Don’t forget the importance of ethical and sustainable choices in today’s fashion world. Troubleshooting common mistakes and employing proper sewing techniques will ensure a smooth application. With these valuable insights and tips, you can confidently craft suits that exude elegance, style, and comfort, leaving a lasting impression on any occasion. Happy tailoring!

Contact Us today to purchase the best Fusible Interlining for your tailoring needs.