Introduction

The garment manufacturers always try to produce appealing garments every single day. For this purpose, they put all their efforts and skills into producing high-quality garments. They aim to get more immediate sales through their garments.

However, there is an essential and invisible piece of garment that most manufacturers underestimate. This piece of garment is referred to as interlining.

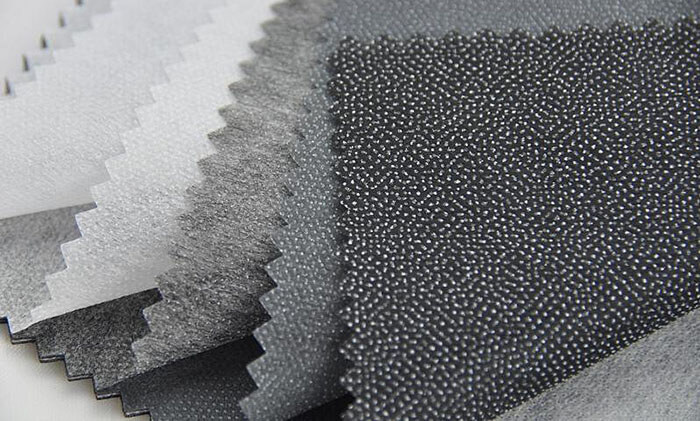

One of the essential types of garment interlining is fusible interlining. This Interlining was started in the early 1950s. Since that day, fusible interlining has played an essential role in garment manufacturing. The quality of your garments hugely depends upon the quality of interlining inside them. Therefore, it is essential to get yourself a high-quality fusible interlining.

You may find getting the right quality of fusible interlining challenging if you are a beginner. It is a fact that several companies, traders, suppliers, and manufacturers are available in the market. Such a situation can make it hard for you to choose and know the original quality of fusible interlining.

If you are also going through the same difficult situation described above, look no further. This article has all the primary guidance for you. You can learn about the basics of your fusible interlining to the factors about choosing the right one. All you need to do is continue reading this blog.

What Is Fusible Interlining?

In clothing, the Base fabric is coated on one side with a thermoplastic adhesive resin through which, with the help of controlled heat and pressure, it can be bonded to another fabric. This process is called fusible interlining. These materials are also called fusible materials. Some of the properties that increase the look of garments are

- Critical areas are controlled and stabilized.

- Augmentation of specific design features

- Preserve the fresh look and crisp

Fusible Interlining Construction

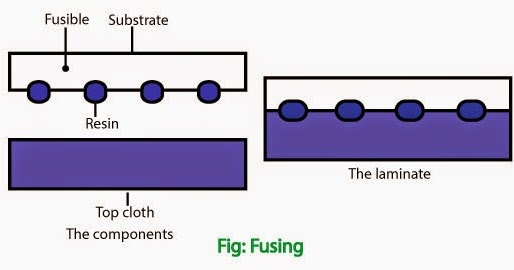

The process of fusible interlining construction consists of three things.

✔Base material

✔Thermoplastic resins

✔ Coating

If you want to know how all these materials work together, continue reading.

Base Materials

Woven, non-woven, and knitted materials are called base materials or substrates. Each has its applications according to its function in making garments. These can be produced from natural and as well as synthetic fibers.

Thermoplastic resins

Bonding between the substrate and top bond is with the help of thermoplastic resins. Synthetic resins melt when heat is applied, and when it is cooled, it is back to its original solid state.

Coating

The coating is the amount of resin deposited on the base fabric. Two aspects of Coating are density and coating system.

Density is applied to the fabric in three different densities

✔Low density

✔Medium density

✔High density

These densities are actual mass per unit volume of resin material.

Why Should You Prefer Fusible Interlining?

As mentioned earlier, fusible Interlining was introduced in the 1950s, still considered the most demandable Interlining for garments. Professional and amateur designers use fusible interlining to reinforce different parts of garments. It is done the same way a seam fiber or stitch is used. Fusible Interlining can be used in several different ways.

Fusible interlining plays essential roles in different ways. Some of those ways can take a bit more time. Now let’s understand why it is used in most garments. You must have seen a lot of garments that contain rigid collars compared to the other fabric of the garment. This rigid part is called interlining. Fusible Interlining is preferred here since it keeps the fabric harder.

Another reason to prefer fusible Interlining is that fusible Interlining can be fused easily. Moreover, this material is also preferred for the repair of different clothes. You can get rid of holes in your clothes without the need to sew them. Fusible Interlining is considered perfect for several projects, such as producing bags, purses, wallets, and curtains.

Stitches on the shirt are also reinforced by fusible interlining to hold more weight and pressure. Fusible Interlining is also used to increase garment quality.

Characteristics of Fusible Interlining

In Fusible interlining, components of garments are heated and pressurized for a certain period. It is necessary to set perfect conditions to carry out the treatment. You have to set a particular temperature range, time, and pressure. The temperature for fusion is 165 to 170, and fusion time is 2-20 seconds, and pressure depends upon the fusion techniques.

- Temperature matters a lot when working with interlinings. Therefore, a particular temperature is used during fusing, so there is no chance of hampering the cloth color.

- You should use 175 degrees as the maximum temperature in fusible interlining.

- You should use 110 degrees as the minimum temperature in fusible interlining.

- For the bonding between interlining and garments fabric, you should use the minimum temperature in the fusing process, or the bond will be disturbed during washing or end-user garments.

- It would help if you did not damage the fusible Interlining bond between garments due to washing or dry cleaning.

- In the clothes, there would be stiffness and drape after fusing interlining.

- The color of fusible Interlining is usually transparent or white. Different fusion requirements may result in a different color.

- Fusible Interlining should be used as it doesn’t change the color of the garments when applied.

- Fusible Interlining should not have any harmful effects on the human body through garments.

Advantages Of Fusible Interlining

There are many advantages of fusible interlining. Some of them are given below.

- You can easily find fusible interlining in the market and get it whenever you want.

- The fusible interlining process of application is straightforward.

- Fusible interlining productivity is high, so it is very profitable.

- The total time in the fusible lining to fuse the product is less than other methods.

- Fusible Interlining is very cheap. Even the lower middle class can use it.

- The performance criteria of fusible Interlining are perfect. People who are using it are pleased with the product.

- The fusible Interlining gives the same outlook of the garments.

- For large production fusible Interlining gives you good productivity.

- Labor cost in fusible Interlining is cheap; hence more profit in using fusible interlining.

Disadvantages Of Fusible Interlining

There are also disadvantages of fusible interlining some of them are given below.

- For the use of Fusible Interlining high temperature is used in the process of fusing.

- During the process of attaching, special interlining care is needed.

- Machine elaboration is required in case of use.

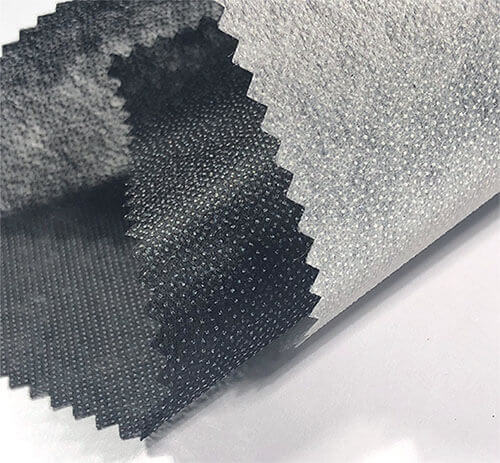

Different Types Of Fusible Interlining

As you know, getting mixed up with different fusible interlinings is straightforward. There are many types available in the market with multiple manufacturers as well. If you get no one to guide you about the right type, then choosing according to your requirements can become a nightmare for you. So this is how you need to separate the wheat from the chaff.

Note that you can buy the fusible interlining through online shops or go to stores yourself. However, it would be best to research to get a good piece for yourself. An expert tip is that you can also follow some accounts on Pinterest to get a good quality of interlinings. You can gain inspiration from those accounts.

While searching for the right Interlining, you should also keep an eye on partnering with the proper manufacturer. You must check their online stores and website reviews to avoid scams. Some main types of fusible Interlining are listed below:

Non-woven Fusible Interlining

Non-woven fusible Interlining is more specifically used in bags and purses. As the name suggests, it is not a woven fabric but rather like cardboard or sheets of paper. This type of fusible Interlining helps reinforce the bottom of the bag. Using this interlining for your clothes can be a bad idea. There is also a version that is thin as paper.

Woven Fusible Interlining

Woven fusible Interlining is much like actual woven fabrics. This type of Interlining helps finish your wardrobe. Its light and flexibility are perfect for strengthening other materials.

Different designers use this in different ways to avoid waste. If you know of weaving, you will also know how the material is put together in this fusible interlining.

Waterproof Fusible Interlining

Waterproof fusible Interlining is a valuable material with a waterproof layer on it. It can make cloth or fabric water resistant. It becomes rigid and stiff.

Double-Sided Fusible Interlining

Holes in clothes, especially jeans, are removed by double-sided fusible interlining. Double-sided fusible interlining bonds the fabric on both sides, and it is straightforward to use, just like double-sided tape

Decorative Fusible Interlining

Decorative Fusible Interlining is used by adding patches, badges, and hiding holes from your clothes to make your wardrobe more stylish.

Quilted Fusible Interlining

Quilting a piece into fabric is done with quilted fusible interlining. This method does not need to add foam and sew, but you have to fuse the interlining, and the work is done. Even if you do not have warm fabrics like flannel or fleece, you should use interlining for quilting your clothes.

It would help if you used the correct fusible interlining mentioned above; depending upon the need, there are also many other types of fusible interlining.

How Do We Use Fusible Interlining

The fusible interlining process is straightforward; you only have to choose the proper fusible method. If you have found what you need the interlining for, these methods are mentioned below to apply fusible interlining to get better results.

- Figure out the size you are going to need to leave some extra fabric if you are going to repair a hole.

- Cut the required area, then locate the interlining where it is needed. French steams are not required here.

- Fusible interlining behave as the glue which is getting heated. To make your glue melt use Iron which will melt the glue and stick to the clothes.

- Iron should be in every part of the fabric for at least 30 to 40 sec before moving forward or backward. Do not hang back to press the Iron for better results.

- Leave the Iron to stand before moving the Iron to make sure that every part of the fabric joins together correctly.

- There is a chance glue might end up on an iron board, so place some cotton underneath to protect everything.

- Using cotton fabric, shield your Iron itself since removing the glue that is covered in Iron is tough.

How To Choose The Right Fusible Interlining?

You need to follow some tips to choose the right fusible interlining. First of all, it must be clear that you have learned about the basics of fusible interlining. Now, this can become a lot easier for you to choose the one that fits your requirements. Secondly, there are some essential factors listed below:

- You should select the fusible Interlining with lower melting points. It is because artificial fabrics are quite sensitive to pressure and temperature.

- You should select polyester and polyamide adhesive linings with excellent adhesion performance. Polyester and polyamide synthetic fiber fabrics cannot easily eliminate the nonabsorbent ironing wrinkles.

- Make sure you choose a thin fabric with a thin fine adhesive liner.

- It would help if you chose elastic fusible Interlining with elastic fabric.

- Don’t try to choose the coarse adhesive lining with low pressure when there is an uneven surface of the fabric.

- It is easy to produce gelatinous or infiltration reflection through translucent or transparent fabric. You should choose a similar color, fine gelatinous adhesive lining.

- Make sure that your fabric is easily ironable. Moreover, it should not contain any texture. In such a case, choosing fusible Interlining can be the best decision.

- It would be helpful if you never chose an interlining that weighs heavier than your fabric. It should always weigh lighter than your fabric.

- You need to consider the stiffness level and the size of the area that you have to stiffen through fusible interlining.

- It is great to have your hands on different types of fusible interlining. It can help you to match the perfect one for your fabric.

- It would be best to consider choosing between a manufacturer and a trader. Manufacture owns a factory and costs you very little compared to a trader. The best part is that you can even get a customized order.

- Lastly, don’t forget to consult with the manufacturer or an expert to help you choose the right one.

Conclusion

Fusible Interlining is the essential component of garments these days. It highly affects the quality of your clothes. Therefore, choosing the right one matters a lot. If you are looking for a high-quality manufacturer for fusible interlining, don’t forget to Contact Us now.