Introduction

Interlining is a cloth used between two layers of fabrics in garments to control and support garment areas. It is also helpful in retaining the actual shape and reinforcement of garment areas.

You can use Interlining by applying it to the base fabric by bonding and sewing. Interlining cloth can be composed of different fabrics and it might be hard to judge the quality.

Most people buy Interlining clothes but they don’t know how to judge their quality. If you are one of those people then don’t worry. This article has everything that you need to know.

You need to continue reading till the end to know how can you judge the quality of interlining.

What Is Crinoline?

Crinoline is a stiffened structure that is used to stand out the long skirt of women. It also refers to a fabric that is composed of horse hair with linen and cotton.

The horse hair is called crin therefore the material is known as crinoline. It was used as a dress lining for women.

Crinoline is the term also used for nylon stiffening tape used for interlining in the 21st century. Nowadays, crinoline is made of different materials and one of those materials is plastic.

The interesting point to note is that it originated as dome-shaped in the 1850s.

What Is The Material Composition Of Interlining Cloth?

Interlining is generally made of flexible, thick, and soft fabric. This fabric may have different varieties such as wool and viscose or their blends, polyester, and nylon. The fabric of interlining may also be coated with different raisins. In garments production, there are two most common types of Interlinings. These types are:

✔Fusible Interlining

✔Non-Fusible Interlining

The interlining of the fabric is chosen very carefully. It is to ensure that interlining can withstand during the care and maintenance of your dress.

Note that Interlining is also known as interfacing. The interlining is used for adding body and structure to your garments.

Different Types Of Interlining

Nowadays, Interlinings are categorized based on two main factors. These factors can be either the base fabric structure or the application point.

Interlining is categorized into three main types based on its base structure:

✔Woven Interlining

✔Non-Woven Interlining

✔Knitted Interlining

On the other hand, it is categorized into two main types based on application point. These categories are :

✔Fusible Interlinings

Fusible Interlining is becoming popular in textiles like curtains as well as other garments. You can say that this attaching interlining is a fabric with hot melt glue on both sides or one side. A controlled fusing application of heat and pressure is utilized to bind one fabric to another. It combines base materials, thermoplastic resins, and coating.

✔Non-Fusible Interlining

It is the additional fabric layer added between the regular lining and outer fabric of your garments. Non-Fusible Interlining doesn’t involve chemical bondings just link fusible Interlining.

Nowadays, the most popular types are Fusible Interlining and non Fusible Interlining.

Production Technology Of Interlining Cloth

The production technology used for Interlining cloth is based upon the wood production system. The whole process takes place in the following steps:

- Base Cloth Bleaching

- Dyeing

- Finishing

- Glueing.

The whole process is explained in the Important points listed below:

✔For high-quality Interlining cloth production, woven base cloth is selected. The cloth can be polyester cotton yarn, polyester silk, and cotton yarn. The selected cloth possesses high fatness, good toughness, and uniform thickness.

✔There are certain requirements for woven base cloth. For example, the surface weaving requirements are given below:

- It should be flat.

- The dry cleaning of warp and weft should be done.

- It should have a uniform density.

- The warp and weft should not be broken.

✔The base cloth should be rinsed thoroughly to remove impurities.

✔During the finishing process, the design of the woven base cloth is finalized.

✔After the finishing process, the stiffening agent is applied to the Interlining cloth.

✔Softener finishing is applied to soften the cloth.

✔To make sure that warp and weft don’t shrink, resin finishing is applied.

✔Finally, the required width of the Interlining cloth is selected by finalizing the design.

✔Make sure that warp and weft don’t move to the yarn when finishing is performed.

✔In the case of the nonwoven base cloth, you have to choose high-quality raw materials. In this case, you have to choose nonspinning good toughness. The cloth must be smooth, uniform with good tensile fatness.

✔Powder coating is also performed in the Interlining production process. In this process, you have to fully transfer the hot melt powder. During the transfer process, you have to ensure that it is transferred evenly. Make sure no powder leakage occurs during powder coating.

✔Make sure that the weight range of right and left width is 1-5 grams.

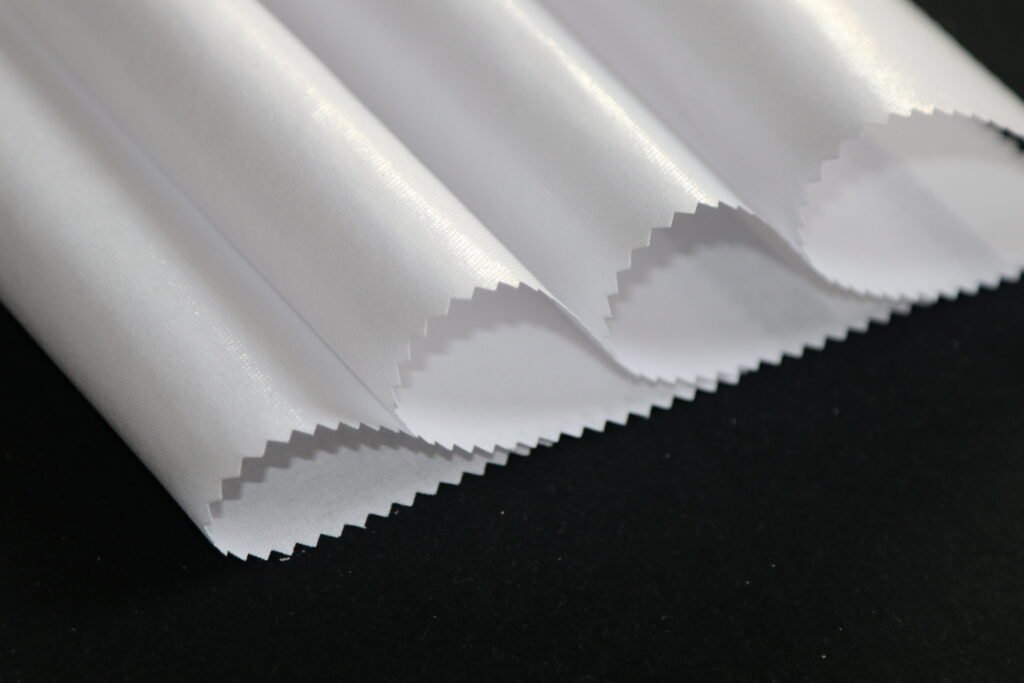

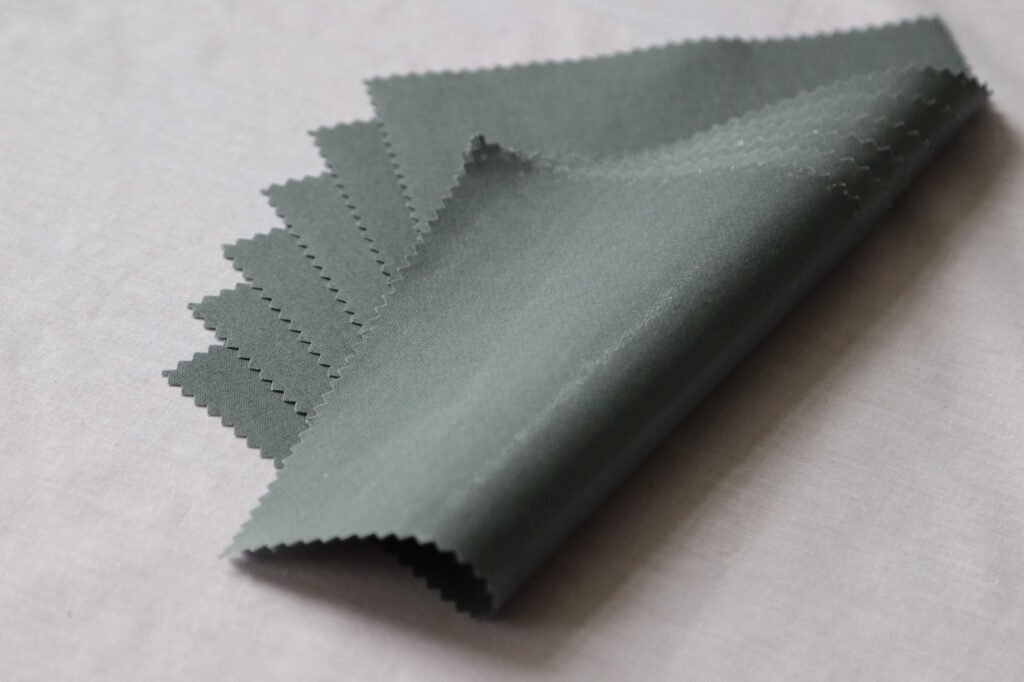

Appearance Quality Of Interlining Cloth

When inspecting the appearance quality of your Interlining cloth, you have to make sure a few points. These points are listed below:

✔The surface of your Interlining cloth should be uniform and smooth.

✔There shouldn’t be any cotton knot on the Interlining cloth.

✔There shouldn’t be any miscellaneous yarn.

✔The Interlining cloth should be free of thin and dense roads.

✔The colouring of the main fabric should be uniform and the dying is performed evenly on the cloth.

✔The width of your Interlining cloth should be consistent.

The Intrinsic Quality Of Interlining Cloth

✔The base cloth should have tear fastness.

✔After heating and bonding, the stripping strength must meet the standard requirements.

✔The thermal shrinkage and shrinkage of the interlining must meet the standard requirements.

✔The content should be free of formaldehyde and meet the standards.

✔It is to be noted that different countries possess different quality standards.

✔Make sure your Interlining cloth matches the right standards.

The Bottom Line

The Interlining cloth plays an important role as extra linen between the layers of fabric and ordinary cloth of your garments. It is important to buy a high-quality type of interlining fabric for your garments business.

If you are looking for high quality and skilled manufacturer, then don’t forget to Contact Us now.