Introduction

Ensuring the shirt’s interlining doesn’t shrink too much is important because it keeps our clothes in good shape. The interlining is like the layer inside the shirt that helps it keep its structure. If it shrinks too much while making the shirt, it can cause problems. For example, the shirt might not fit well anymore or not last as long as we want.

Think about your favourite shirt – it wouldn’t be nice if it suddenly didn’t fit or got all weird after washing it a few times, right? That’s why we need to control how much the interlining shrinks. In this blog, we’ll figure out why stopping too much shrinkage is so important. It’s not just about comfort; it’s also about making sure our favourite clothes stay good for a long time.

What Is the Manufacturing Process?

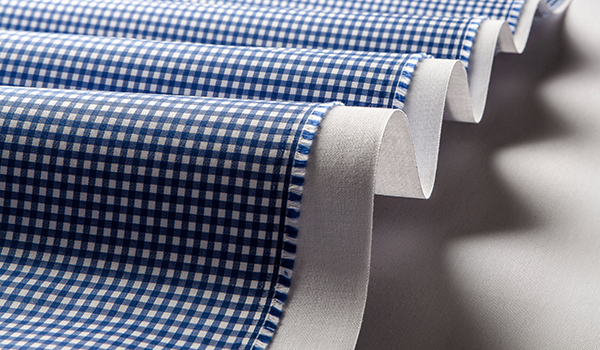

The making of shirt interlining involves a series of steps to create that inner layer giving structure to our shirts. Let’s break it down:

Steps Involved in Shirt Interlining Production

The process kicks off with selecting the materials. Manufacturers carefully choose fabrics that can handle the wear and tear of daily life. Then comes cutting – where these materials are shaped into the right pieces. Stitching follows, putting those pieces together to form the interlining layer. After stitching, the interlining goes through a pressing stage, where it gets its final shape and smoothness.

Factors Contributing to Shrinkage

Now, let’s dive into why shrinkage can happen:

Types of Interlining Materials

The materials used play a big role. Some fabrics tend to shrink more than others. So, choosing the right material is crucial to control shrinkage.

Production Techniques

The way manufacturers put things together matters. Precise and standardized techniques help prevent unwanted shrinkage during production.

Environmental Conditions

Believe it or not, where and how the interlining is made matters. Humidity and temperature can influence shrinkage. So, manufacturers need to be mindful of their production environment.

How Does It Impact Shirt Quality?

Understanding how shirt interlining shrinkage impacts quality is key for manufacturers and consumers. Let’s break it down:

Distorted Fit

Impact on Collars and Cuffs

Shrinkage can mess with the way collars and cuffs sit on a shirt. They might become too tight, making the shirt uncomfortable to wear. This can be a real bother for anyone looking for a crisp, comfortable fit.

Effect on Overall Silhouette

The overall shape of the shirt is at stake. Too much shrinkage might alter how the shirt hangs on your body, creating an awkward silhouette. It’s like trying to fit into something that used to be your size but isn’t anymore.

Reduced Durability

Increased Wear and Tear

Shrinkage can weaken the fabric, making it prone to wear and tear. This means your favourite shirt may not withstand the rigours of daily use as well as it should. The material isn’t as sturdy as it used to be.

Shortened Lifespan of the Shirt

When a shirt’s quality is compromised, its lifespan takes a hit. You’d want your favourite shirts to last, but excessive shrinkage can cut short their time in your wardrobe.

Negative Aesthetic Effects

Wrinkling and Creasing

Too much shrinkage can lead to wrinkling and creasing, giving your shirt an unkempt appearance. It’s like wearing something that looks crumpled, even if you just took it out of the closet.

Compromised Appearance

Overall, excessive shrinkage compromises the appearance of the shirt. What once looked polished and well-fitted might end up looking sloppy and ill-maintained.

What Is the Level of Customer Satisfaction?

Checking how happy customers are is super important for shirt makers. Let’s see why:

Importance of Consistent Sizing

Getting the size right every time is a big deal for customers. Think about grabbing a shirt you love; suddenly, it fits all weirdly because it shrank. That’s annoying! Makers must ensure sizes stay the same so customers know what to expect and stay happy.

Influence on Brand Reputation

When shirts don’t keep their shape, it’s not just a problem for the person wearing them. It’s also bad for the brand’s reputation. Brands want people to trust them; consistent quality is a big part of that. If shirts keep shrinking unexpectedly, people won’t be happy, hurting the brand’s good name.

Customer Feedback and Reviews

What customers say in their reviews is a big deal in online shopping. If many say, “Hey, these shirts always shrink!” it’s not good for the brand. Makers must listen to customers and fix any problems to keep everyone happy.

How Is Environmental Sustainability Addressed?

Exploring the environmental side of things is crucial for manufacturers. Let’s break down how they tackle it.

Cost of Returns and Exchanges

When shirts have issues like unexpected shrinkage, people return or exchange them. This costs money for both the customer and the manufacturer. It’s like a double expense – the shirt has to be remade, and the old one might not even be usable. By making sure shirts don’t shrink too much, manufacturers can cut down on these unnecessary costs, helping the environment and their wallets.

Impact on Production Efficiency

If the manufacturing process isn’t efficient, it can harm the environment. Extra steps or mistakes mean more energy and resources are used, which isn’t great. By focusing on efficient processes that limit mistakes, manufacturers can reduce their environmental impact.

Long-Term Financial Implications for Manufacturers

Manufacturers need to think about the long-term regarding their wallets and the environment. If shirts are always shrinking, it can lead to more returns and exchanges. This means more materials wasted and more work redoing things. By investing in better processes upfront, manufacturers can save money and reduce their environmental footprint in the long run.

What Strategies Are Employed for Controlling Shirt Interlining Shrinkage?

Ensuring the shirt interlining doesn’t shrink too much is pretty straightforward. Let’s break it down in simpler terms.

Quality Control Measures

Testing and Inspection Protocols

Before turning materials into shirts, we ensure they can handle everyday wear without shrinking too much. It’s like giving them a thumbs-up before turning them into your favourite shirt.

Standardized Manufacturing Processes

We have a set way of making shirts to control shrinkage. Every shirt goes through the same steps in the same order, so there are no surprises. It’s like following a recipe to ensure it turns out just right.

Innovative Materials and Technologies

Advances in Interlining Materials

Scientists and makers are always finding better materials. We use fabrics that resist shrinkage, so your shirt stays the same size after washing. It’s like upgrading to a stronger material for a longer shirt.

High-Tech Production Techniques

We use clever tricks in making shirts to prevent shrinkage. It’s like having a high-tech tool that ensures every shirt is perfect. These tricks smooth the process, creating shirts that stay in good shape even after many washes.

What Economic Considerations Are Involved?

When making shirts, it’s smart to consider a few things that help the planet and make economic sense.

Considerations for Eco-Friendly Practices

Using Resources Wisely

Using materials and energy wisely isn’t just good for the planet; it’s good for saving money. We spend less when we waste less, making the whole process more affordable.

Cutting Down on Waste

Being careful about waste isn’t just about being eco-friendly but saving money. When we reduce waste during production, we’re also cutting unnecessary expenses.

Balancing Quality Control and Sustainable Manufacturing

Keeping Quality High

While being eco-friendly is important, we also want to keep making shirts that people love. Quality shirts mean happy customers, more sales, and a great reputation for the brand.

Saving Money in the Long Run

Sustainable practices might need a bit of investment upfront, but they pay off in the long run. From using less energy to creating less waste, these practices help us save money over time.

Conclusion

Stopping shirts from shrinking too much is super important. It makes sure our clothes fit well and stay looking good for a long time. When shirts shrink too much, they get uncomfortable and don’t look as nice. This can make people unhappy and even hurt the brand’s reputation.

By using smart tricks when making shirts, like checking materials and using better techniques, we can avoid these problems. It’s not just about making shirts; it’s about making shirts that people like and that last a long time. So, controlling shrinkage isn’t just a techy thing – it’s about ensuring our favourite shirts stay the way we like them.

FAQs

Why Is Interlining Important in the Garment?

Interlining adds structure and shape to garments, enhancing their durability, fit, and overall appearance.

What Is Interlining in Shirts?

Interlining in shirts is a layer of fabric sandwiched between the outer and inner layers, providing support and structure.

What Are the Advantages of Fusible Interlining?

The fusible interlining offers easy application through heat, improving garment stability and shape retention and simplifying the manufacturing process.

What Is the Interlining Process of Fabric Manufacturing?

The interlining process in fabric manufacturing involves adding a supportive layer between fabric layers. This enhances the textile’s structure and overall performance.

Contact us today to purchase the best quality interlining shirt without shrinkage.