Introduction

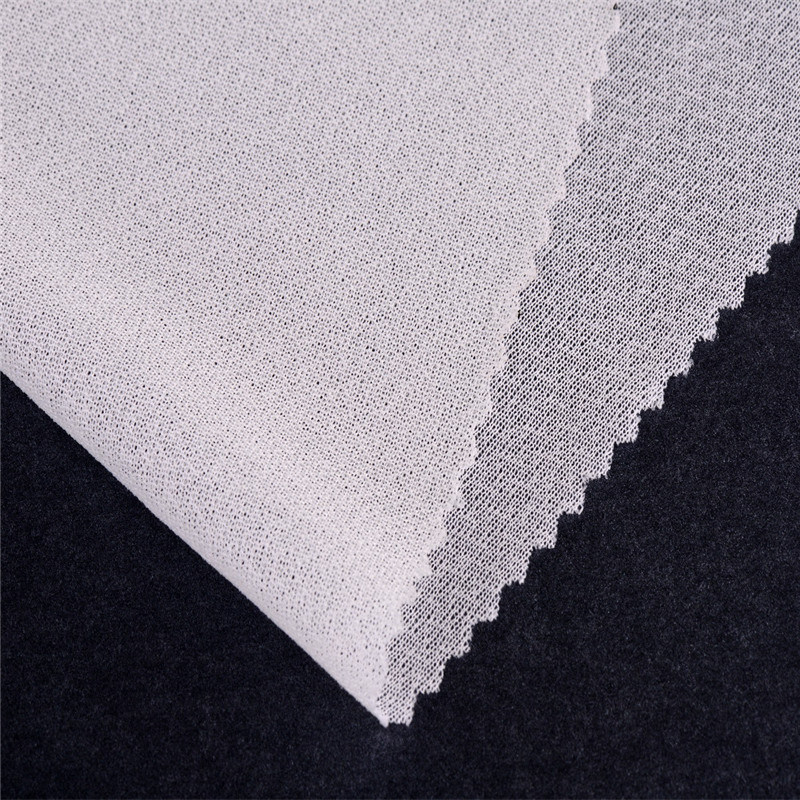

You must know the importance of interlining for your garments. They help create a stable shape for your garments. Moreover, interlinings also play a big part in improving the quality of your garments. Interlinings exist in two primary forms. These two forms are fusible and non-fusible interlining. The latter is also known as sew-in interlining.

Interlinings are attached to those parts of the fabric that are responsible for supporting the shape. Collars, waistbands, cuffs, and button packets are some most targeted parts for interlining. Even though interlining has great importance and works like magic, it can also cause some defects. But the defects occur only when you choose the wrong interlining.

It can affect the quality of your fabrics when you attach the interlining incorrectly. You must know that not all interlining can be applied similarly. You have to adopt different ways to connect a fusible interlining.

While there are different ways to attach a sew-in or non-fusible interlining, we must know that 90% of manufacturers use fusible interlining before proceeding further.

Therefore, this article will teach you how to attach a fusible interlining. Let’s begin our journey.

What Is Fusible Interfacing?

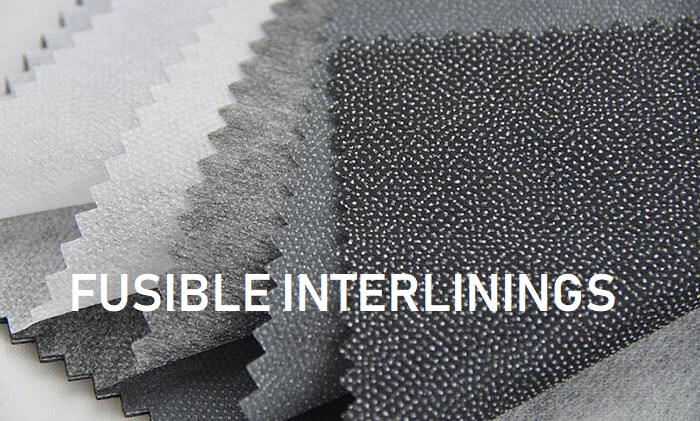

Fusible interlining is the most commonly used type of interlining. The name of this interlining suggests that it is applied with the help of the fusing process. However, it requires a particular amount of pressure and heat to fuse perfectly. At the same time, you must maintain a specific duration when applying the fusible interlining.

Any increase or decrease in time when applying heat and pressure can result in a wrong interlining attachment. The manufacturers give you special instructions on the time, temperature, and pressure required to use fusible interlining. You can find this interlining mainly used in ready-made and bespoke garments.

Fusible interlining is readily available in the market since you can find 90% of interlining as fusible. The process of applying fusible interlining is simple and easy. Moreover, it gives you fantastic performance at a meager cost. Finally, you have to consume less time while applying a fusible interlining.

Note that you have to take special care when applying this interlining. Don’t forget to take help from an expert and check the manufacturer’s instructions. You must know the required amount of heat and pressure for this interlining. Fusible interlinings also exist in multiple forms. Let’s explore them.

What Are Different Types of Fusible Interfacing?

It is important to note that fusible interlining is used for all garments. Apart from being a famous interlining, fusible interlining also improves the appearance of your garments. This interlining allows you to stabilize and control some more crucial parts of your fabrics. It is also used to strengthen the design features of your materials.

However, there is also a possibility that all these properties vary with the type of fusible interlining. Here are a few most common types of fusible interlining.

Polyethylene coated interlining

- It is used as a resin coating.

- This type of fusible interlining is mainly used in cuffs and collars.

- You can wash the fabric in water attached to the fusible interlining.

- The varying density effect of resin aims to achieve a more excellent resistance. It helps to dry clean solvents. At the same time, it helps to achieve a higher softening point with the increase in density.

PVC coated interlining

- Just like various other interlinings, PVC is also used as resin coating.

- This type of fusible interlining is equally suitable for washable and dry cleanable garments.

- The interesting fact to know is that most of the coat garments are made from PVC-coated interlining.

Polyamide coated interlining

- You must know that you can use polyamide as a coated resin.

- Dry cleanable garments mostly use poly-amides.

- Polyamide interlining requires a high-temperature fusing. Moreover, they are washed with water at 60 degrees Celsius.

Polyester coated interlining

- You must know that polyester is a less water-absorbent resin when compared to polyamide.

- It is a resin coating that can be used in different garments.

- You must know that polyester-coated interlining is known to be an ideal interlining.

- However, it is costly but available easily in the market.

PVA coated fusible interlining

- PVA-coated interlining contains a limited washability that is not so much dry cleanable.

- The most common applications of this interlining are leather and fur materials.

- You have to maintain a low temperature and pressure for this interlining.

- PVA-coated interlining is rarely used in the garments manufacturing industry.

Polypropylene coated fusible interlining

- This interlining has a resin that is much similar to the polyethylene-coated interlining.

- You must maintain a high temperature to fuse this interlining to the fabric.

- This interlining and the fabric attached can be easily washed with water.

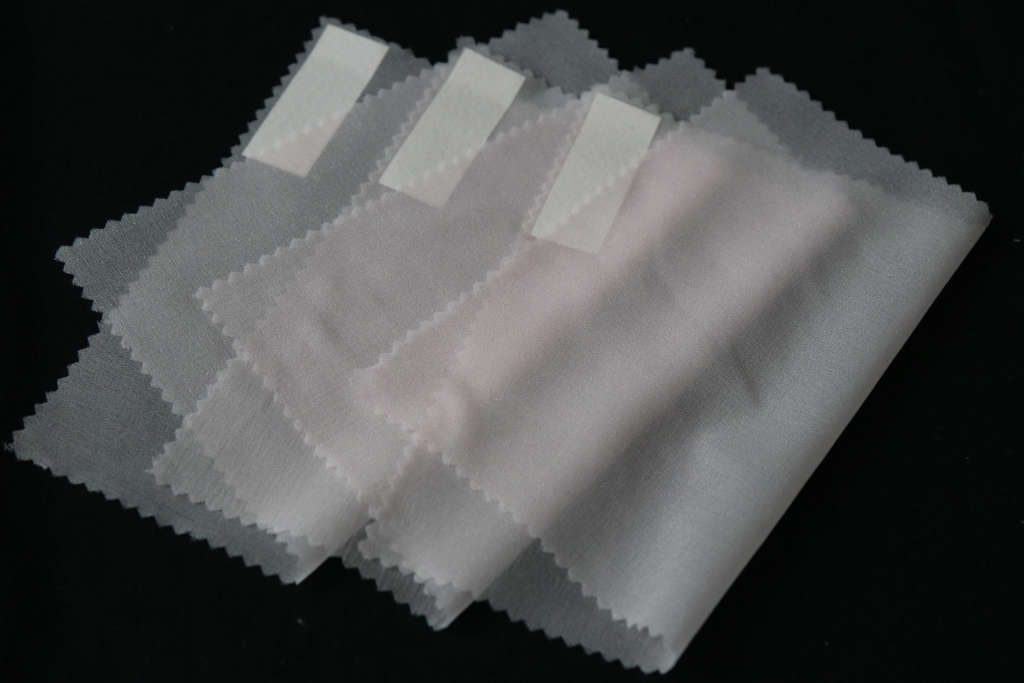

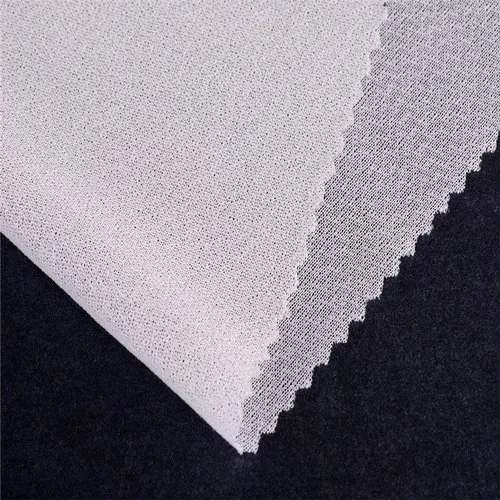

Apart from these types, fusible interlinings also have classes that are woven, nonwoven, and knit fusible interlinings.

What Do You Need to Attach Fusible Interlining?

Fusible interlining is a convenient tool that is worth your time to learn about it. But attaching or applying this interlining in the right way also takes effort. Before we proceed toward applying fusible interlining, it is essential to keep our things prepared. Here is a list of things you must have when attaching your fusible interlining to the fabric.

- Fabric that requires fusible interlining.

- Fusible interlining that must be smaller than your fabric piece. It should be about ¼ inches from the cutting edge.

- Iron with high or medium settings.

- Pressing cloth

- Spray bottle filled with water.

You must know whether your fabric will take the fusible interlining or not. However, if you don’t know about them, don’t worry. This is because we have also listed some fabrics that don’t take the fusible interlining. Let’s check the materials given below.

Which Fabrics Do Not Take Fusible Interlining?

Although fusible interlining is easy to apply and has 90% applications, some fabrics don’t take it. These fabrics are better attached with sew-in interlining. When selecting the right fusible interlining, you also think about the type of fabric. Here is the list of materials you can’t use with a fusible interlining.

If you are using fabrics that don’t have any stretch, then fusible interfacing in woven type is correct.

When dealing with stretchable fabrics, you must use tricot knit interlining.

You must not use a heavy fabric with a heavy fusible interlining. Instead, take a lightweight fusible interlining. If you want a crisp look for your materials, you must choose weft insertion fusible interfacing.

The fabric you use must have a smooth side for the interlining to bond. This is the most important rule to use the fusible interlining. Fusible interlining is applied to the smooth sides of your fabrics.

Ensure there is no unevenness on the fabric when applying the fusible interlining. Fusible interlining works best for most garments. However, you must avoid it for the following materials:

- Napped fabrics (fur/velvet)

- Very textured fabrics

- Heat sensitive fabrics

- Materials with an open or very loose weave.

Sew-in interlining would work best for the materials listed above.

What Is The Process Of Attaching Fusible Interlining?

Now that you have learned about fusible interlining and which fabrics to use let’s move on to attach it. In this process, we will take a small piece of fusible interlining and attach it to our targeted fabric. Note that the interlining amount will be smaller than our targeted fabric. This is always recommended, and you must have read this rule in the above sections.

You will be tracing the small interlining fabric when tracing the sewing pattern. Before trimming, you must cut it about 1/4th inch from the fabric edge to avoid bulk.

It would be best if you placed your interlining on the board with the right side down. The wrong side of the interlining is smooth and soft. Then, it would be best if you placed your pressing cloth on both pieces. It should be a thin cotton fabric piece.

Then, you have to spray the pressing cloth till it becomes damp. You must keep your iron to a medium or high setting. After properly damping the fabric, press the iron for 10 to 15 seconds. Repeat this step until the whole interfacing is correctly attached to the fabric.

With optimal dampness and optimal iron heat, the pressing cloth will always be dry. Now, you can see that the interfacing is attached correctly, no matter how you fold it.