Introduction

Using interlining in different types of garments is very popular these days. As a garments manufacturer, you must know the importance of interlining in your clothes. It would help if you had an idea of how choosing the right weight, the right type, and the right quality of interlining affects the posture of your garments.

Sometimes, it cannot be easy to know, but this article will help you.

Now even if you know the importance of choosing the right interlining for your garments, there can be some issues; for example, you might not be able to see how you can use it within different applications. You may adopt various methods to insert interlining between two layers of fabric.

At the same time, it is also essential to know about safety measures that you need to pay attention to. Otherwise, you may end up just destroying your garments and interlining them. It can lead to wasting your money and time. So this article focuses on all those aspects you should pay attention to when using interlining. Continue reading

What Is Interlining?

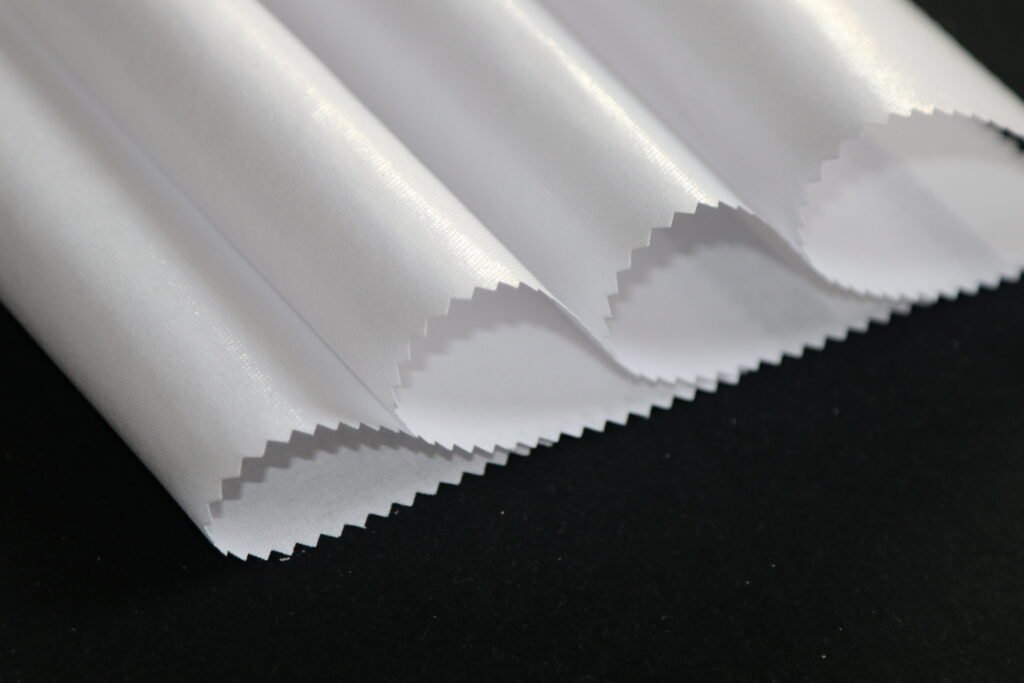

If you are a regular and professional manufacturer of garments, this term might not be new to you. Interlining is just a fabric used between two external layers to support the overall attire. You can use it for various purposes. For example, you can use it either for retaining the shape or maintaining the posture of your dress.

In simple words, interlining works more like magic. Nobody can see it, but it controls the structure of your garments while hiding inside them. Many experts have also called it a secret weapon to make your main fabric look superb. Now you must be thinking about how someone can use it. Well, there are several methods to use interlining; sewing and bonding.

You should also know that interlining can be composed of different clothes. So it is also essential that different interlinings be used with different clothes based on their properties. Interlining is also interfacing, so you should not confuse these terms.

Do you want to know why you should use interlining in your garments‘ construction details? Understanding why you should use something before investing in it is essential. So continue reading to learn the same about interlining.

Why Should You Use Interlining In Your Garments?

Before proceeding toward the direct answer, let’s give you an example. You must be aware of fleece clothes. You must have seen it as a coat when you purchase it through online shopping. You may also have imagined how to wear it. And it must feel like a well-structured coat lining correctly with your shoulders.

However, when you receive your parcel, you must be disappointed to see that it is just a fleece cloth. It might be comfy and soft, but it might not be able to maintain a proper body posture. It is where you can take help from interlining.

There are two sides to every garment—the one that shows outside and the other that touches your body. You can use interlining between these two layers. You have to sew or bond it so that nobody can see it. An interlining gives a stiff but comfortable structure to your body.

You feel like your body is in proper shape when wearing garments having interlining as a separate layer.

So, it would be best if you used interlining to control the structure of your garments.

Moreover,

✔Interlinings are stability, support, and strengthening of the clothes.

✔It helps to prevent distortion in clothes due to stress.

✔It Improves the hand feel and aesthetic property of the dress.

✔It Enhances the lifespan of your clothes.

Can You Use the Same Type Of Interlining With Different Garments?

Using the same type of interlining with every cloth or garment is not the right decision. You should know that different types of interlinings are available in the market. So, you should use the correct type of interlining with suitable garments. You have to notice that types of interlining are categorized based on applications and fabric structure.

Some most common types of interlinings available in the market are given as under:

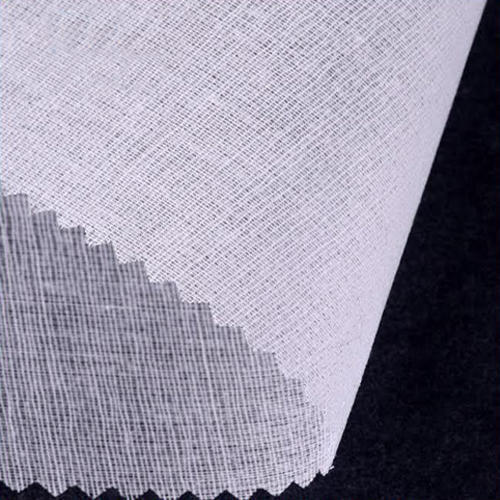

Based On The Fabric Structure

✔Woven interlinings, non-woven interlining, knit interlining.

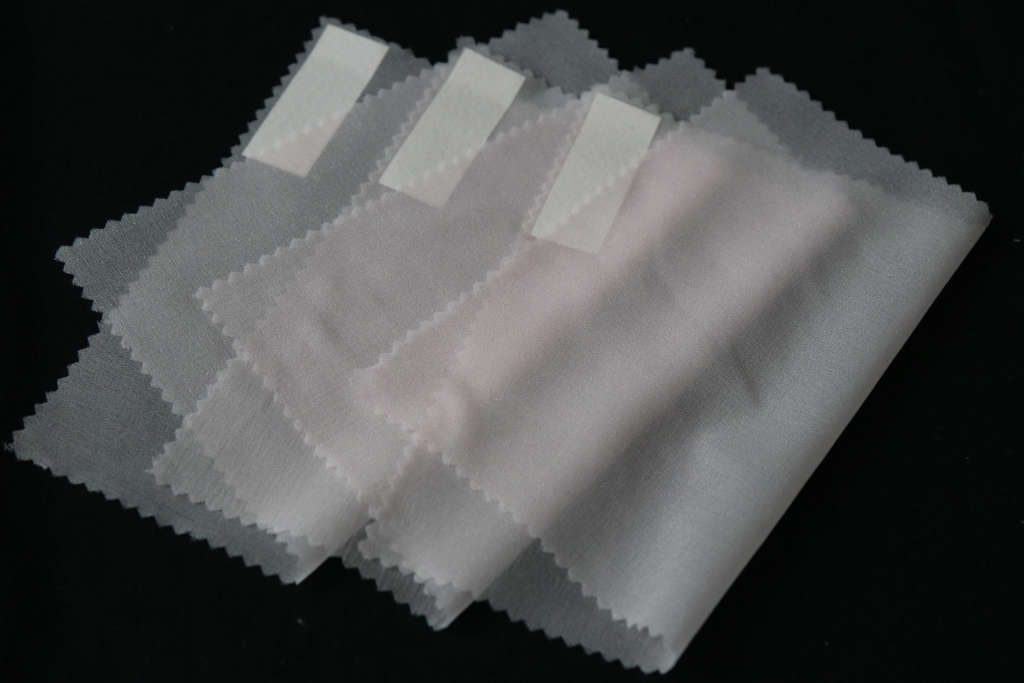

Based On The Applications

✔Fusible interlining, non-fusible interlining.

Is It Important To Consider the Weight When Using Interlining With Our Garments?

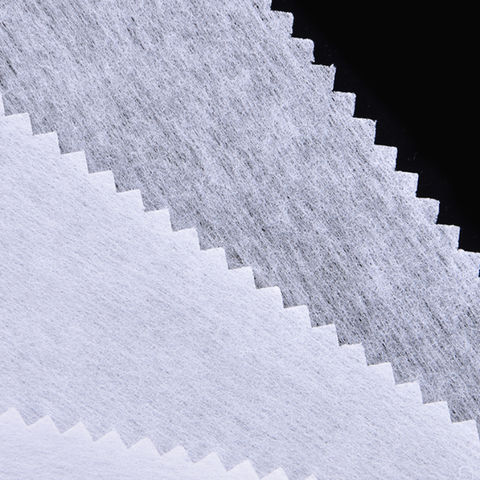

As mentioned earlier, you must choose the right type of non-woven interlinings with suitable garments. Most people also miss the point of selecting the correct weight of interlining for their attire. It would be best if you chose an interlining based on the weight of your garments. For example, for lightweight garments, you should not attempt to select a heavy interlining.

Interlinings are also categorized into different weights for finished garments with different weights. These are organized into light-weight, medium-weight, and large-weights. In most cases, medium-weight interlinings are used. On the other hand, you can use heavyweight interlinings for applications such as purses.

You should use a lightweight interlining with cotton lawn fabrics.

Heavyweight interlinings are also used in most winter clothes. They intend to provide warmth when you wear those clothes. According to experts, you should ensure that your chosen interlining weight is a little smaller than the weight of your garments.

You should also consult with the interlining seller to help you select the correct weight of interlining for your garments.

How To Use Interlining With Different Applications?

You should know that interlinings can be used through different methods. For example, you can sew it or bond it. If you plan to fuse an interlining with your garments, you should consider the following points.

✔You have to ensure the smoothness of your shell fabric. For this purpose, you must wash your material and iron it. It will help to ensure flatness and smoothness by removing wrinkles.

✔Place the fabric on the ironing board.

✔Find the adhesive side of the interlining and place it with the wrong side of your cloth.

✔Apply heat by ironing the cloth. You have to ensure an even heat application.

✔Keep lifting the iron to the new position to ensure the heat is applied to all parts.

✔Move the other side and apply heat in the same way as you did for the previous side. It will help to achieve a solid bonding.

✔Make sure the heat is applied evenly, and there are no wrinkles or non-flat surfaces.

You may need to take care of your garments when applying interlining to them. For example, there are different methods for nylon, polyester, classic shirts, or jersey shirts.

Important fact: Interfacing is an additional layer that acts like magic or secret weapon in your own clothes.

Is It Important To Select A High-Quality Interlining? If Yes, How?

The quality of interlining also matters when selecting the correct weight of interlining. The quality of interlining determines whether your garments will last longer or not.

You need to pay attention to the appearance quality of interlining and the intrinsic quality of interlining when using them. So how can you pay attention to appearance and inherent quality? Read here:

Appearance Quality To Observe When Using Interlining

✔The interlining surface should be uniform.

✔No cotton knot should be there on cloth.

✔No miscellaneous yarn should be there.

✔There exist no dense roads on interlining material.

✔Dying and colouring of cloth should be even.

✔The interlining fabric should have a consistent width.

Intrinsic Quality Of Interlining

✔There should be tear fastness in the base cloth.

✔The interlining fabric should meet the manufacturing standards regarding strength and bonding.

✔There should be no formaldehyde in the content of the sheer fabric.

✔The quality should meet the standards of your country.

What Is the effect Of Time, temperature, And Pressure Of Bonding In The Use Of Interlining?

When you are using interlining, you have to take care of three main factors. These factors are time, temperature, and pressure. All three factors have a particular effect on the peeling strength. To a particular point, these factors and the peeling strength are directly proportional to each other. When you reach an optimum or highest point, they become inversely proportional to each other.

When you deal with thin fabric, you should use a small glue point interlining for your interlining cloth. It will help to adjust the adhesive machine’s temperature, pressing time, and pressure to achieve the best results. At the same time, the thin fabric is easy to bleed when you use small glue point interlining.

What Safety Measures Should You Take When Using Interlining?

Safety measures are essential to know whether you use heavy machines or apply interlining on clothes. These measures can help you gain the desired output without harming yourself, your product, or your environment. Some necessary safety measures that you should pay attention to when using interlining are given below:

✔Put the cloth properly on the ironing boards to prevent wrong fusing.

✔Make sure you put the interlining on the wrong side of the material.

✔It would help if you did not overheat the iron. Otherwise, the base knit fabrics and interlining will be burned.

✔Don’t try to touch the iron when performing the fusing process on outer fabric pattern pieces.

✔Make sure the interlining and garment fabric properties match each other. For example, lightweight interfacing for lightweight fabric.

✔If you use the sew-in interlining, ensure the sewing needles are not broken. Otherwise, it can cause injuries.

✔Try to have a comfortable seat when sewing the fusible interlinings, which may cause backbone pain.

✔Too much noise can cause noise pollution in the environment. It can disturb people in the surrounding. Make sure you choose a suitable place to carry out interlining work.

Conclusion

To achieve a high-quality interlining application, you should take proper safety measures. It would help if you also chose a high-quality interlining with properties matching your garment.